Your main limiting factor there will be the ball valve.

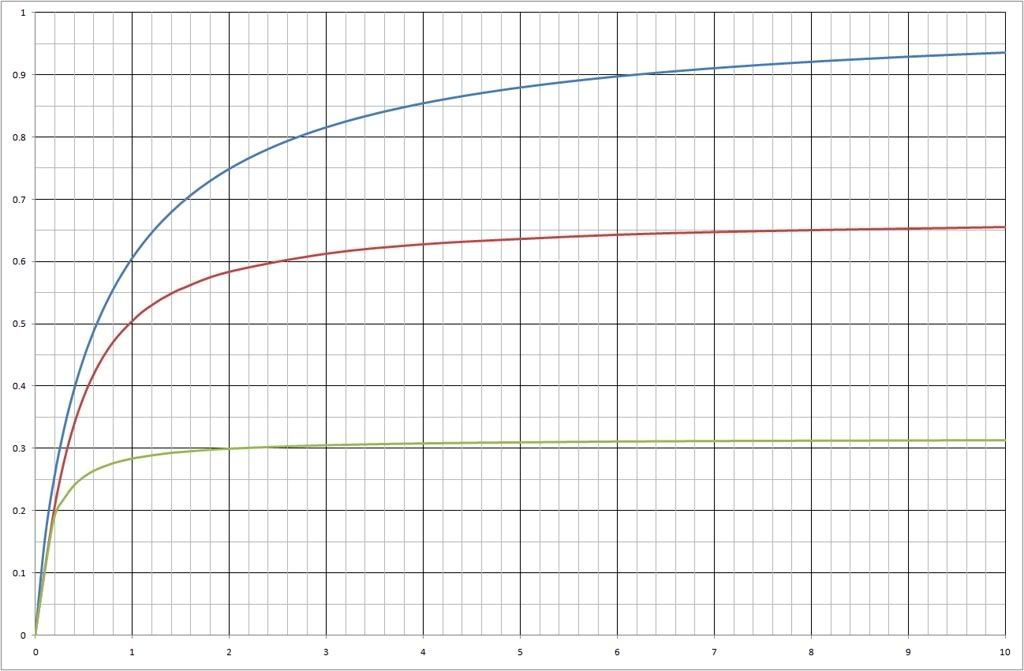

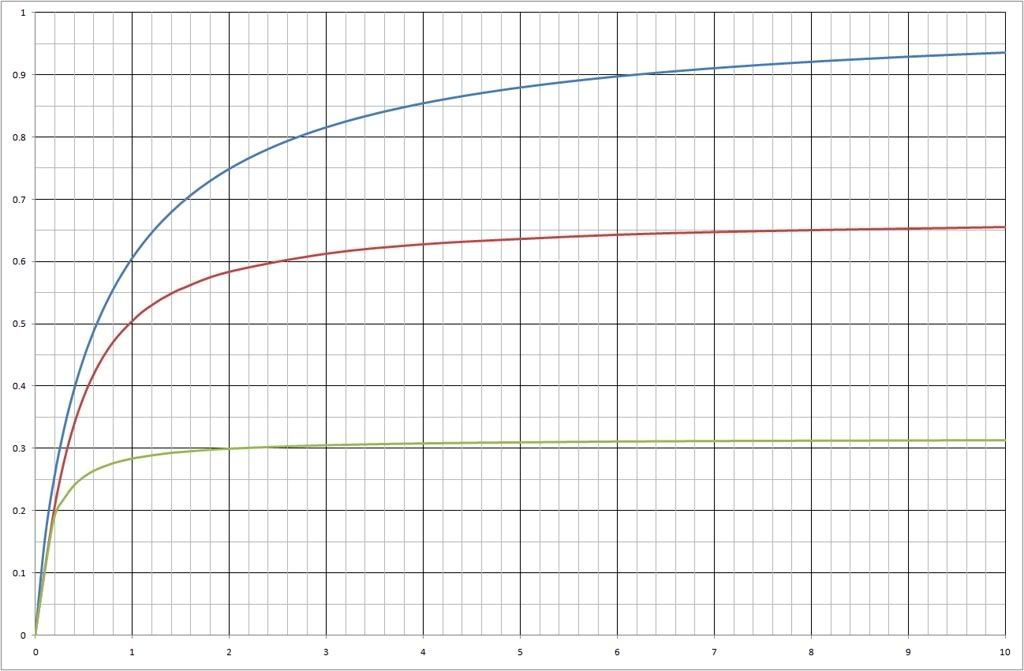

Here's some simulated results I did a few years ago to demonstrate:

The X-axis is the relative volume of the chamber compared to the barrel, or the "C:B ratio" as it's called. A value of 1 is an equally sized valve and chamber, a value of 2 is a chamber double the volume of the barrel and so on and so forth.

The Y-axis shows the muzzle energy relative to the theoretical maximum (with an infinitely sized chamber and no flow losses anywhere in the system.)

The blue line is performance with no flow losses, but a finitely sized chamber. As you can see, increasing chamber size does increase muzzle energy, but at heavily diminishing returns.

A C:B ratio of 1:1 has ~60% of the theoretical performance, but a C:B ratio of 2:1 only improves that to ~75% - in other words, twice as much pumping for only a quarter more energy.

The red line is with a full-bore piston valve (a good valve, but nonetheless limited by the laws of physics) and a moderate weight projectile. Energy does still improve as the chamber size increases, but it's much more limited. By a ratio of about 6:1, the curve is almost flat, and there's very few gains to be hand.

Also note that it "peels away" from the perfect blue line - It's pretty close to the same performance below about 1:1, but the relative performance gap is proportionally much bigger at higher ratios.

This effect is even more pronounced with the green line, which is essentially the same valve as above, but half the diameter (and thus a quarter of the flow). While it's similar to the other systems below about 0.25:1, the line is nearly flat by about 3:1.

In this system, increasing the C:B ratio from 5:1 to 10:1 would have absolutely no discernible effect, because the limiting factor is the valve.

These are the results that most resemble your system, because while ball valves have excellent flow when they're fully open, they're very slow to open. If you're opening it fairly fast, it might take a tenth of a second, but even pushed by the little air that gets through the valve, a small projectile like that will be gone in a fraction of that.

If the valve isn't letting most of the air through anyway, then adding extra chamber volume is nearly pointless - that extra air just won't get into the barrel in time, and all the added effort is just turning into sound and fury, signifying nothing. (To quote Shakespeare).

Personally, I'd say even a really good valve would be hitting the sane limits of diminishing returns at around about 2:1 C:B ratio, and you're already at around 4:1.

You'd get massively more out of lengthening your barrel (which gives the projectile longer to accelerate, and also gives a slow valve more time to open) and/or improving the valve.

My recommendation for the valve would be a spring-loaded ball valve (as a suitably beefy spring can open the valve a lot faster and smoother than is possible by hand - just make sure you don't pinch your fingers in it)- while this won't be as fast as a pneumatically actuated valve, it will be a lot simpler to build; things like piston valves can be a bit fiddly at early stages, and you might find it difficult to find a commercial quick exhaust valve.