First coaxial piston gun

Posted: Wed Apr 16, 2008 2:51 am

I've been fighting wi-, er, um.. working on this one for a couple of weeks now. The previous iterations of this gun featured non-serviceable pistons, which ultimately were a bad idea. I'm building this as a learning tool, so to speak...to better understand the ins and outs of a piston valve. So, a serviceable piston was a must. I've gotta say, apparently the third time's a charm, 'cause this one actually works quite well. On to the specifics...

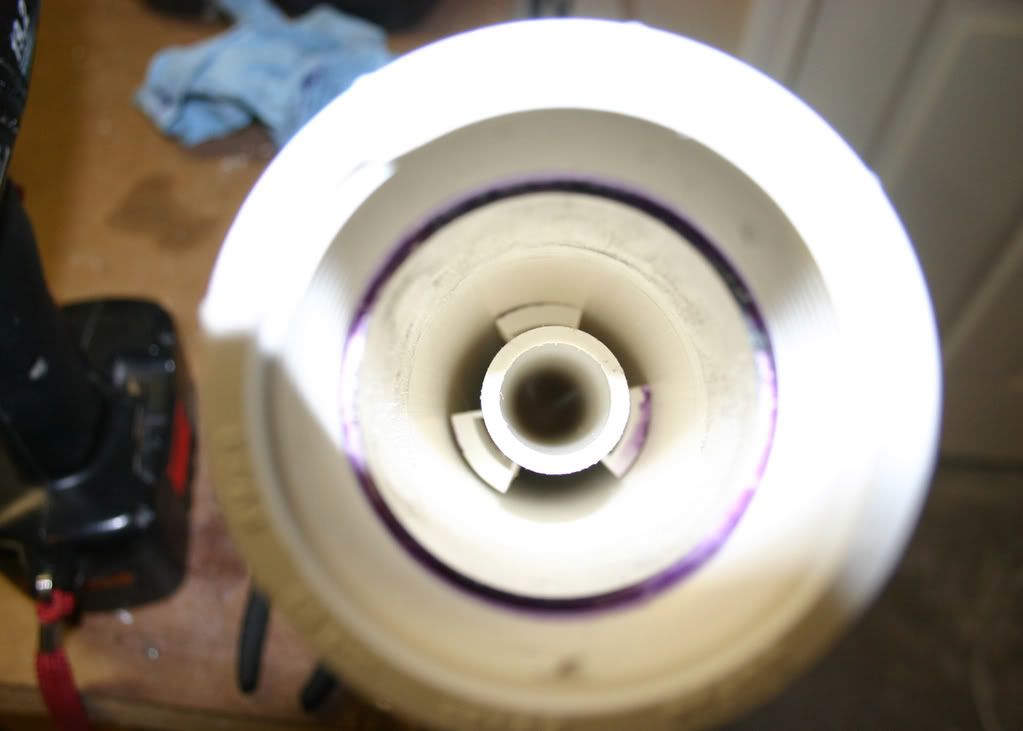

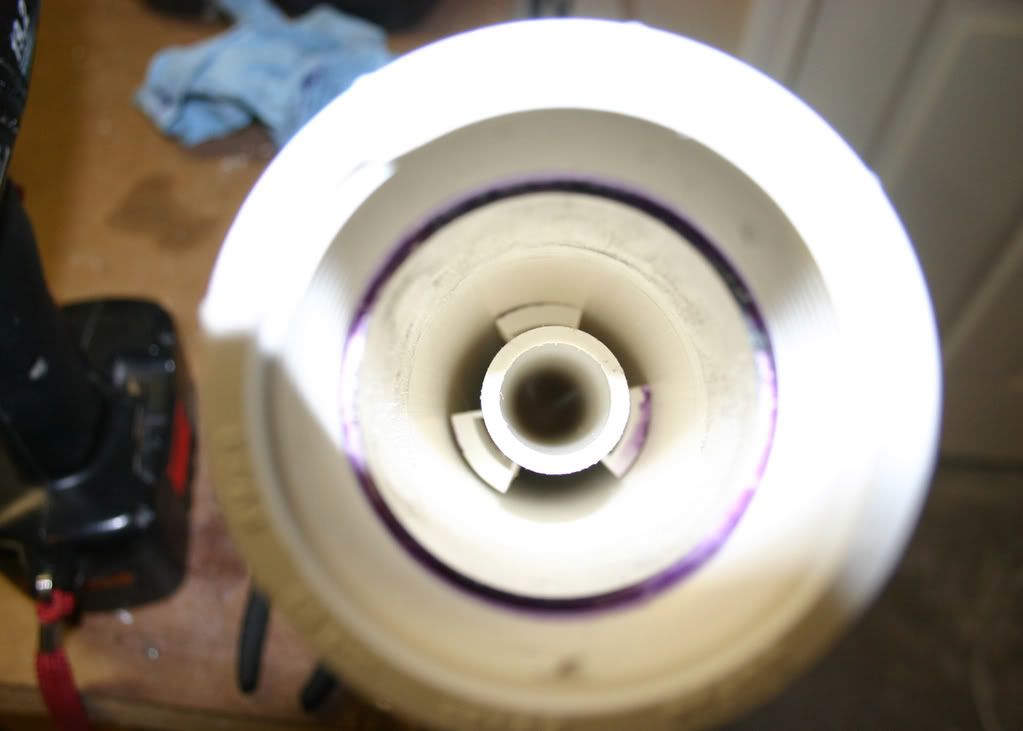

The chamber is 2" sch 40 and the barrel is .75" sch 40. The business end is just a 2"x.75" reducer bushing with the flange dremel'd out of it and the barrel (sloppily) welded flush.

To keep the barrel centered, I again dremeld the flange out of a 1.5"x.75" reducer bushing and cut small wedges out of it. A little epoxy to hold them in place and it works nicely.

The piston (which I had previously described <a href="http://www.spudfiles.com/forums/sanding ... l">here</a>) is the rubber cylinder from a 2" sanding drum and a handful of nuts, bolts and washers. I scrapped the inner tube sealing face in favor of a 2" neoprene washer, which works much better.

Finally, a couple thread adapters (I didn't know they made those nsf-pw...pleasant surpise, indeed), .75" sprinkler valve/blowgun, schrader valve and a guage. (please forgive my messy workbench)

Despite a little sloppy primer work, I'm pleased. All I wanted was a simple little plinker to fool around with. Just with the few low pressure shots I've made while testing the piston, I've been surprised by the "thump" this thing produces. I'll put it through its paces tomorrow. I have to admit, however, this is one of the smaller guns I've built and I'm a little dubious as to what kind of pressure it will take.

Either way, lemme know what you think. I know there must be some obvious short-comings, and I wanna know what they are so the next one will be better. I'll try and get some video up tomorrow, as well.

The chamber is 2" sch 40 and the barrel is .75" sch 40. The business end is just a 2"x.75" reducer bushing with the flange dremel'd out of it and the barrel (sloppily) welded flush.

To keep the barrel centered, I again dremeld the flange out of a 1.5"x.75" reducer bushing and cut small wedges out of it. A little epoxy to hold them in place and it works nicely.

The piston (which I had previously described <a href="http://www.spudfiles.com/forums/sanding ... l">here</a>) is the rubber cylinder from a 2" sanding drum and a handful of nuts, bolts and washers. I scrapped the inner tube sealing face in favor of a 2" neoprene washer, which works much better.

Finally, a couple thread adapters (I didn't know they made those nsf-pw...pleasant surpise, indeed), .75" sprinkler valve/blowgun, schrader valve and a guage. (please forgive my messy workbench)

Despite a little sloppy primer work, I'm pleased. All I wanted was a simple little plinker to fool around with. Just with the few low pressure shots I've made while testing the piston, I've been surprised by the "thump" this thing produces. I'll put it through its paces tomorrow. I have to admit, however, this is one of the smaller guns I've built and I'm a little dubious as to what kind of pressure it will take.

Either way, lemme know what you think. I know there must be some obvious short-comings, and I wanna know what they are so the next one will be better. I'll try and get some video up tomorrow, as well.