Harness the power of precision mixtures of pressurized flammable vapor. Safety first! These are advanced potato guns - not for the beginner.

-

jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Mon Jul 11, 2011 11:20 am

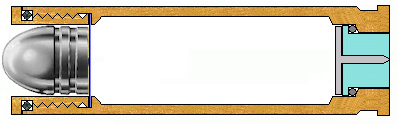

Lemauditpouravoirabandonnésonamourdelacomplexité wrote:Alright, here's a better insulated-no thread-no glued-self sealing one

You're getting the hang of it

Gun Freak wrote:So what's to stop you from insulating the valve stem?

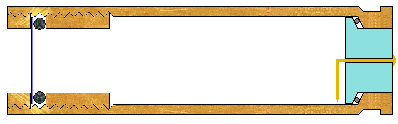

Technically this could work, what I don't like is the bolt poking into the cartridge, this could cause issues with ejection. I've ensmallened the valve stem to allow it to be dropped out through the mouth of the cartridge in case the seal needs replacing.

-

Attachments

-

- untitled.gif (15.45 KiB) Viewed 2929 times

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

dewey-1

- Sergeant 3

- Posts: 1298

- Joined: Wed Mar 28, 2007 10:24 am

- Location: NE Wisconsin USA

Mon Jul 11, 2011 11:29 am

Darn you LeMaudit, you beat me to the same idea I was working on!

Guess that is what happens when you use a Paint program rather than a 3D CAD program.

I guess now I will wait until you two finalize it.

-

LeMaudit

- Corporal 2

- Posts: 665

- Joined: Thu Apr 16, 2009 2:48 pm

Mon Jul 11, 2011 11:36 am

Darn you LeMaudit,

I am already.

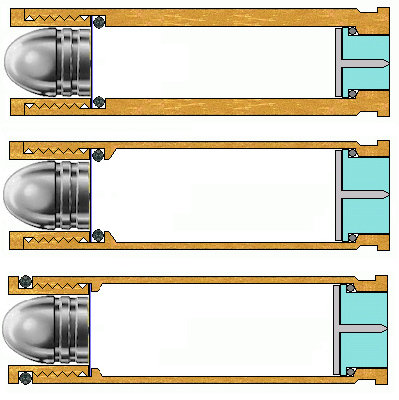

Here's another one, now I understand better the problem and in case dewey1 is working on another drawing:

- plastic plug that can slide to be used as the refil valve

- sealing with no need for a precise o-ring size

- hole can be made with a standard drill bit

- the electrode is a bended brass pin.

-

Attachments

-

- plastic3.jpg (22.01 KiB) Viewed 2917 times

-

jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Mon Jul 11, 2011 11:36 am

Gun Freak wrote:Or using a plastic one?

... and what would you use for an electrode then?

dewey-1 wrote:Darn you LeMaudit, you beat me to the same idea I was working on!

Great minds eh

LeMaudit wrote:I am already.

I think the irony is lost here

- plastic plug that can slide to be used as the refil valve

- sealing with no need for a precise o-ring size

- hole can be made with a standard drill bit

- the electrode is a bended brass pin.

You might just be on to something...

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

Gun Freak

- Lieutenant 5

- Posts: 4971

- Joined: Mon Jan 25, 2010 4:38 pm

- Location: Florida

- Been thanked: 8 times

Mon Jul 11, 2011 11:45 am

jackssmirkingrevenge wrote:... and what would you use for an electrode then?

Duh

Remember I've never made a hybrid 8)

What keeps the stem from falling out when there is no pressure in the cartridge? I see how it would be easy to put it back in but it would be a pain to do all the time.

-

jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Mon Jul 11, 2011 11:52 am

Gun Freak wrote:Duh

Remember I've never made a hybrid

The correct answer is "I haven't made a hybrid yet"

Gun Freak wrote:What keeps the stem from falling out when there is no pressure in the cartridge? I see how it would be easy to put it back in but it would be a pain to do all the time.

Nothing, and yes it's a huge pain in the arse.

LeMaudit, I modified your design slightly. The aluminium insert gives all round spark gap potential and also reinforces the synthetic bit to make it less likely to blow out on ignition.

What I don't like about this is that the rear seal cannot be serviced.

-

Attachments

-

- untitled.gif (12.12 KiB) Viewed 2906 times

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

Mon Jul 11, 2011 12:02 pm

do you really need a servicable plug ??

untitled.gif - can be serviced as far as I can tell

Children are the future

unless we stop them now

-

LeMaudit

- Corporal 2

- Posts: 665

- Joined: Thu Apr 16, 2009 2:48 pm

Mon Jul 11, 2011 12:02 pm

LeMaudit, I modified your design slightly.

Be my guest

What I don't like about this is that the rear seal cannot be serviced.

What do you mean? You can access it from the front, by unscrewing the threaded rings...

oh... right... the inner one is epoxied...

Me what I don't like is the thread... working on removing it

-

dewey-1

- Sergeant 3

- Posts: 1298

- Joined: Wed Mar 28, 2007 10:24 am

- Location: NE Wisconsin USA

Mon Jul 11, 2011 12:24 pm

JSR;

Use Loctite thread sealant (blue) rather than epoxy for the threaded insert.

And again LeMaudit beat me to the 118 degree drill angle for the the rear seal. All the my ideas are being used.

The untitled gif looks like the most promising to prevent arcing externally.

-

POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

Mon Jul 11, 2011 12:55 pm

What do you mean? You can access it from the front, by unscrewing the threaded rings... Confused oh... right... the inner one is epoxied

already told him there is no need to epoxy them

Children are the future

unless we stop them now

-

LeMaudit

- Corporal 2

- Posts: 665

- Joined: Thu Apr 16, 2009 2:48 pm

Mon Jul 11, 2011 1:19 pm

Nothing new here, but IMO it's not more complicated to cut it that way (top drawing), you have an easier way to unscrew the front, and it's serviceable.

If the volume need to be increased and you're bored, a tool of the same name will easily cut in one swift movement the intricate internal as shown in the center drawing. You just drill through, insert the boring bar, and cut.

As a bonus in the bottom drawing if you put the o-ring externally, no risk to be damaged by the heat or removed by the blast, and also it may be useful as a seal in the barrel (?) But I'm not sure it would seal the chamber that way.. would it?

-

Attachments

-

-

al-xg

- Corporal 2

- Posts: 643

- Joined: Fri Jan 19, 2007 12:29 pm

Mon Jul 11, 2011 1:26 pm

PTFE, thread sealing paste, hemp thread...

With a groove down the ID to be able to tighten it all up sufficiently with a philips screwdriver or homemade tool.

Edit: D'oh way too slow...

That last one will not seal, there is nothing to keep the o-ring from being pushed out.

I'm guessing the burst disks have to be fairly rigid to not pop out ? Unless the o-ring is compressed in which case there needs to be a gap between the body and the screw in insert for tightening.

Last edited by

al-xg on Mon Jul 11, 2011 1:39 pm, edited 1 time in total.

-

LeMaudit

- Corporal 2

- Posts: 665

- Joined: Thu Apr 16, 2009 2:48 pm

Mon Jul 11, 2011 1:37 pm

That last one will not seal, there is nothing to keep the o-ring from being pushed out.

I was afraid about that

[edit] Right! Last one: Serviceable, & sealed the Dimply way

Now I need to work damnit

-

Attachments

-

- plastic6.jpg (25.89 KiB) Viewed 2835 times