Page 1 of 2

Fuel Injection and Air Mixing....

Posted: Wed Apr 30, 2008 11:15 pm

by D_Hall

Just thought I'd bounce an idea off ya'll. I'm pretty sure it's a sound idea, but still, a fresh pair of eyes never hurts.

OK, proper fuel/air mixing is required for good combustion. Around here that's often done with chamber fans. I'm not saying chamber fans are bad or that I won't use 'em. I'm wondering, however, if their job would be made MUCH easier if an eductor was used.

More to the point, I was thinking: McMaster part num: 5205K24

Feed it propane and air (as appropriate to which step of fueling you're in) and it ought to pull in fuel/air from the chamber to really help the mixing.

Thoughts?

Posted: Wed Apr 30, 2008 11:21 pm

by bigbob12345

Umm good idea but it is very expensive

$45, you could buy like 5 chamber fans with that which would proabably give more flow then this air flow booster.

But if I had the money Id be willing to try it, its an intresting idea.

Posted: Wed Apr 30, 2008 11:25 pm

by BigGrib

i'm not really sure how that thing works, but from the looks of it you'd have to drill a bigger hole in the chamber or something, and you'd still have to meter it exactly as if you have a chamber fan in it. from the looks if it, it only mixes the fuel and would still have the propane sit in one spot instead of distributing the fuel/air mixture evenly throughout the chamber. but like i said i really dont know how that thing works, i'm just guessing here. If you could explain it to me i'd appreciate it.

Posted: Wed Apr 30, 2008 11:43 pm

by starman

I'm not familiar with these things and even studying over them some not sure how or why they work. Low cfm boosted to high cfm through use of another compressed air input.

Can you elaborate some on how they might be utilized in chamber mixing?

Posted: Wed Apr 30, 2008 11:50 pm

by D_Hall

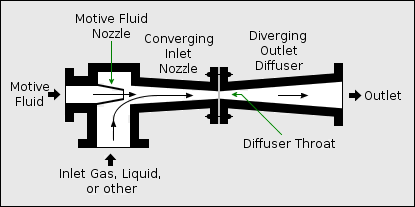

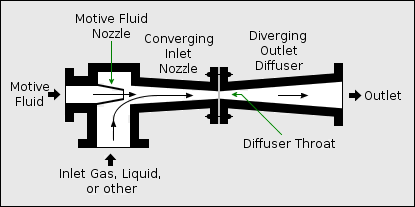

Basically they're tuned eductors/ejectors (same gizmo, different names).

Link to Wikipedia article

Using the above sketch (hope that pic links well).... As I would envision thier use in a hybrid, the motive fluid would the fuel being injected(*). The inlet gas would be the air inside the chamber (yes, the whole thing is inside the chamber). This would mix fuel with air in a very efficient manner while moving large quanitities of air around within the chamber.

(*) And later the supplimental air, but for now we'll just talk about fuel.

Posted: Wed Apr 30, 2008 11:55 pm

by D_Hall

bigbob12345 wrote:Umm good idea but it is very expensive

$45, you could buy like 5 chamber fans with that which would proabably give more flow then this air flow booster.

The one I quoted moves 26.4 cfm; about the same as an 80 mm cooling fan (which tend to go for about $20). The big advantages....

1) It's virtually indestructible.

2) It's inherently safe. No amount of damage to it would ever result in frayed wires or anything that could ever be a safety hazard.

Disadvantage....

1) Once the fuel/air is injected, the mixing is done. You can't just let it run for 20 minutes.

Posted: Wed Apr 30, 2008 11:58 pm

by BigGrib

how would you meter everything with that setup or do you know yet

Posted: Thu May 01, 2008 12:05 am

by THUNDERLORD

Looks sort of like it will only circulate by the "motive fluid" so if the mix was off it would still need to be vented out manually.

Unless it is very precise. But I'm not familiar with the part.

The carburation or fuel injection is interesting though.

Posted: Thu May 01, 2008 12:21 am

by D_Hall

BigGrib wrote:how would you meter everything with that setup or do you know yet

A metering pipe, just like everybody else. The only difference would be that inside the chamber at the fuel injection point you'd find the ejector. The ejector would not affect overall fuel/air mixture one iota. What it WOULD do is aid in mixing fuel/air in the chamber.

Posted: Thu May 01, 2008 12:24 am

by BigGrib

well from looking at it and thinking about it, you could definitely use this to mix the fuel/air but i would still recommend the use of a chamber fan to disperse the fuel throughout the chamber and to blow spent gases from the chamber after firing.

Posted: Thu May 01, 2008 12:53 am

by Lentamentalisk

BigGrib has a point... This thing helps with mixing the fuel, but doesn't do a thing for venting the chamber afterwards, though it is quite an attractive idea. I'm very interested to see how this can be used.

Posted: Thu May 01, 2008 9:31 am

by Hotwired

The solid eductor would certainly be more robust than the average chamber fan.

I can't see a $40 bit of metal making much of a dent in a five figure budget so cost isn't important.

I actually thought you were going to be injecting them together but after reading through more carefully you're looking to separate the two.

Why not have them simultaneously mixed in a carburettor style with an air jet pulling in the fuel from a restricted orifice?

Posted: Thu May 01, 2008 9:52 am

by Lentamentalisk

Hotwired wrote:Why not have them simultaneously mixed in a carburettor style with an air jet pulling in the fuel from a restricted orifice?

What ever fuel is used (unless it is gasoline... Yikes!) it is already going to be under pressure, so that won't exactly work as far as I can see, unless you had some pressure release valve that was triggered by the slight vacuum.

The real issue is that the thing can't push much pressure out at all, so it won't work for pressurizing the chamber.

However, if you stick it inside, then you can do a primary mixing when you add the fuel, and then another mixing by pumping the air through the same inlet as the propane.

Posted: Thu May 01, 2008 10:04 am

by D_Hall

Lentamentalisk wrote:However, if you stick it inside, then you can do a primary mixing when you add the fuel, and then another mixing by pumping the air through the same inlet as the propane.

This is indeed the plan.

As for venting afterwards.... Originally I was planning on pulling a vacuum on the chamber. EXCELLENT purging! After running numbers and such, I realized that I'd save a lot of money and get pretty good results simply by using a couple of 5 HP shop vacs for 30 minutes(*).

(*) Put a 2" ball valve on each chamber leg. Attach hose. Pull air through barre/chamber. Shop vacs (combined) should move 240 cfm. Chamber is 170 cf. Run 'em for 30 minutes and I should be down to negligable remnant combustion gases.

Posted: Thu May 01, 2008 12:38 pm

by jimmy101

Basically, you're talking about a mixing manifold or carburator. The tricky part is getting the mix correct. In a true mixing mainifold you would regulate the pressure of both gases. Pretty darn tricky for propane + air since one is 25x the volume of the other. Small errors in pressure will kill the accuracy of the mix.

I think the eductor will have the same kind of problem as a mixing manifold. How to precisely control the air / propane ratio. Are you thinking of having the eductor injest say all the propane plus half the air to get good mixing then "topping off" the chamber with the rest of the air?

How bout this instead...

1. Evacuate the chamber down to a moderate vacuum, perhaps 0.1 ATM.

2. Pressurize the chamber with propane to your target propane mole fraction + whatever the vacuum was. So, for a 10X mixture, and if the vacuum was 0.1 ATM (1.5 PSIA), you pressurize with propane to 5.9 + 1.5 = 7.4 PSIA. I would think the combination of the low initial pressure in the chamber and the high inlet flow would equilibrate the propane thoughout the chamber pretty quickly.

3. Now inject air at high pressure until the chamber reaches the desired final pressure. The air could be injected simultaneously from several ports.

I believe this is similar to what you posted before. The difference is the order of injecting the gases. Instead of injection 4% of the chamber volume in propane at high pressure you would inject 96% of the chamber volume in air at high pressure. Should give much better mixing.