I wish I had taken some pictures of the piston, but I don't want to take the gun apart again now.

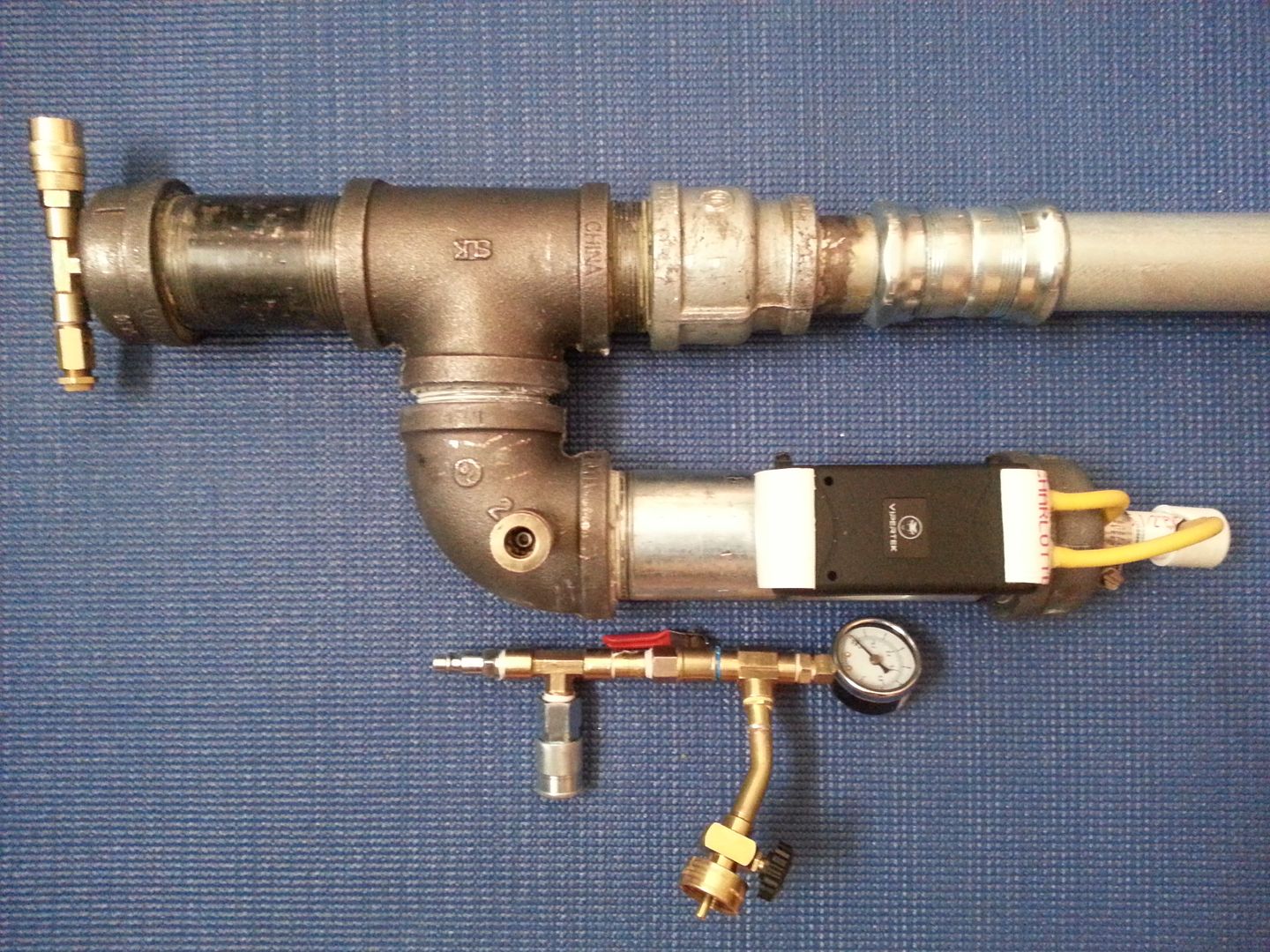

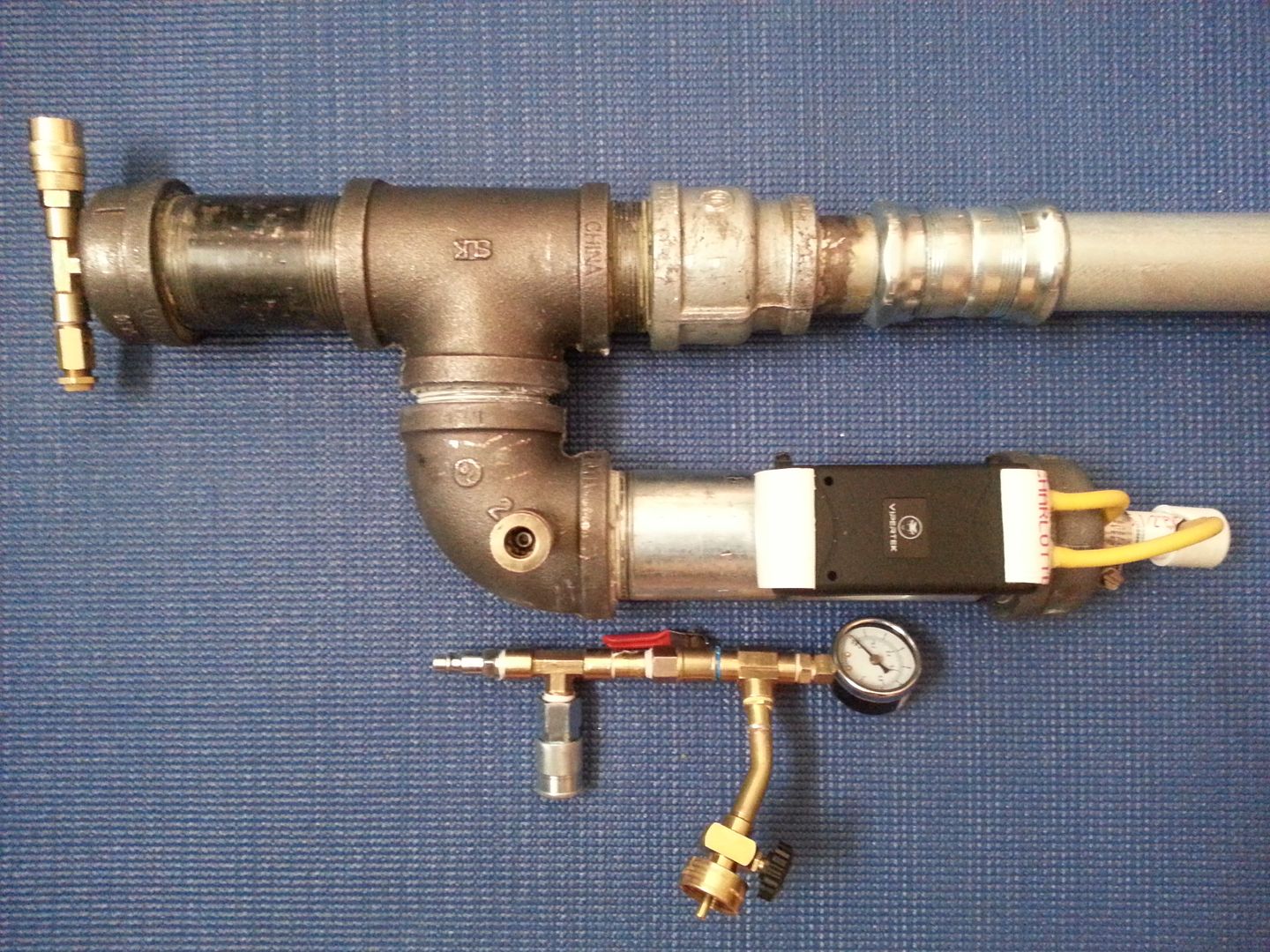

That said here is the external view. It is 2" parts with a 1-1/2" EMT barrel. A $7 ViperTek stun gun and NGK 4629 spark plug provide ignition and there is a manifold for charging using the manometric method.

The pop off valve is a high flow 1/4" one and is adjustable. It has the choice of 4 different springs and the tension on those springs is also adjustable so it has a wide range. Not sure if it is high enough flow, but it seems fast and the pilot chamber is quite small. The pop off goes off with a bang when set at 100 psi if I overcharge past 100 psi. I may be reworking the tee, quick connect, and pop off arrangement depending on how it works out.

Right now it has a stubby little barrel (~20"), but I plan to use a longer one. I have not decided what length to use yet.

Update

Update... At first with the old two piece manifold I was having problems with getting the mix right. The unsuccessful drill was:

1. Plug pump into quick connect for pilot chamber and pressurize to desired pressure.

2. Plug propane manifold into quick connect on chamber and pressurize chamber to desired pressure of propane.

3. Unplug propane manifold.

4. Plug pump into quick connect for chamber and pressurize to desired air pressure.

5. Unplug manifold.

I think the problem was that the quick connect let propane escape when plugging the pump into the quick connect.

The current setup has the pump and propane both connected to the manifold at the same time. A ball valve protects the propane gauge when pressurizing it with air. The whole manifold pops on and off as one piece.

The new and successful drill is:

1. Plug pump into quick connect for pilot chamber and pressurize to desired pressure.

2. Plug combined propane and air manifold into quick connect on chamber.

3. Open the ball valve and pressurize chamber to desired pressure of propane.

4. Close the ball valve.

5. Pressurize chamber to desired air pressure.

6. Unplug manifold.

It seems to work fine now. Oh and it was crazy loud with the short barrel and no projectile.

Now that it is set up and working, I will have to figure out what barrel I really want on this gun. It definitely deserves something longer than the little stubby barrel that is on it now. It was just a leftover piece of EMT. Something in the 5-6' range is probably where I will wind up. Longer would probably be better for optimum performance, but where I usually shoot keeping a lower profile is desired. I figure a moderate length barrel attracts less attention.

Another Update:

Ok, so the rubber face on the piston was quickly shredded. I decided to smooth out and round the breech face that the rubber bears against, but after doing so decided that the tube was thin enough that it was likely to still be a problem. At that point I made a bushing to spread out the load at the cost of restricting flow a bit.

I installed a 42" barrel that I had laying around, but it would definitely benefit from a longer yet barrel. I had been wondering what the gun weighed as I lugged it around so I weighed it and it turns out to be a stout 19 pounds!