Is it ok to make a vortex cap bbmg with parts that have a larger

diameter, so it will take more BBs?

will it make it weaker?

vortex cap bbmg question

- Davidvaini

- Sergeant 4

- Posts: 1315

- Joined: Tue May 29, 2007 8:58 pm

Well the whole point of the vortex cap is so you can use it in smaller applications.. but as far as making the vortex cap bigger.. I wouldnt go past 1 inch.

But that doesnt mean you cant have a larger magazine.. you just need it to adapt down to your vortex cap size.

But if you have the space then nothing wrong with an Inline vortex..

But that doesnt mean you cant have a larger magazine.. you just need it to adapt down to your vortex cap size.

But if you have the space then nothing wrong with an Inline vortex..

Thanx, and, one more thing, is a vortex cap bbmg can shoot up?Davidvaini wrote:Well the whole point of the vortex cap is so you can use it in smaller applications.. but as far as making the vortex cap bigger.. I wouldnt go past 1 inch.

But that doesnt mean you cant have a larger magazine.. you just need it to adapt down to your vortex cap size.

But if you have the space then nothing wrong with an Inline vortex..

and, do i have to shake it to shoot?

- Davidvaini

- Sergeant 4

- Posts: 1315

- Joined: Tue May 29, 2007 8:58 pm

If you install a plunger in the magazine you will not need to shake it.. and same for shooting up.. no problems with shooting it up either.

The p90 vortex cap BBMG which first introduced the vortex cap design has a plunger..

http://www.spudfiles.com/forums/rc-p240 ... 12907.html

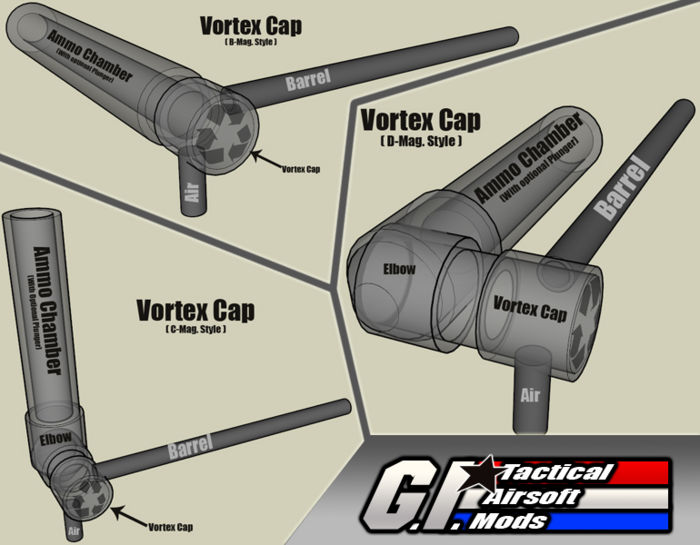

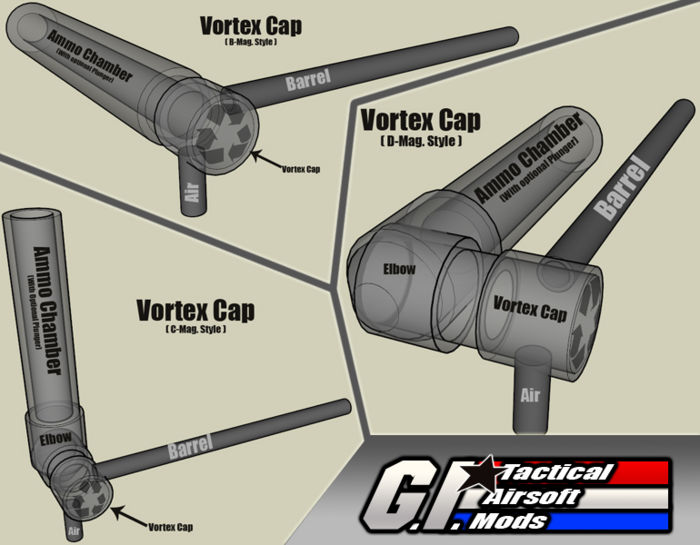

And here is a picture in the wiki to show that the plunger is optional.. but I highly recommend putting one in.

The p90 vortex cap BBMG which first introduced the vortex cap design has a plunger..

http://www.spudfiles.com/forums/rc-p240 ... 12907.html

And here is a picture in the wiki to show that the plunger is optional.. but I highly recommend putting one in.

ok, do you recommend to use a vortex cap with a 90 degree elbow?Davidvaini wrote:If you install a plunger in the magazine you will not need to shake it.. and same for shooting up.. no problems with shooting it up either.

The p90 vortex cap BBMG which first introduced the vortex cap design has a plunger..

http://www.spudfiles.com/forums/rc-p240 ... 12907.html

And here is a picture in the wiki to show that the plunger is optional.. but I highly recommend putting one in.

and, is the nedd to be a strong one?

- Davidvaini

- Sergeant 4

- Posts: 1315

- Joined: Tue May 29, 2007 8:58 pm

Sure, you can use a 90 degree elbow. The "C" and "D" designs actually incorporate an elbow.

As far as your other question is concerned...

"and, is the nedd to be a strong one?"

I'm guessing you are referring to the plunger, I would actually recomend a weaker string if you arnt doing an elbow.. if you are doing an elbow than a medium strength spring is just fine.

As far as your other question is concerned...

"and, is the nedd to be a strong one?"

I'm guessing you are referring to the plunger, I would actually recomend a weaker string if you arnt doing an elbow.. if you are doing an elbow than a medium strength spring is just fine.

- jimmy101

- Sergeant Major 2

- Posts: 3210

- Joined: Wed Mar 28, 2007 9:48 am

- Location: Greenwood, Indiana

- Has thanked: 6 times

- Been thanked: 18 times

- Contact:

Or, omit the plunger and just use an elbow for the "magazine". If the elbow points backwards the gun will fire until nearly empty with the barrel below horizontal. With the elbow forward the gun'll fire till nearly empty with the barrel above horizontal. Use a T (ala Latke) and you can get roughly half the BBs fired in either orientation before you'll need to give the gun a shake.

Actually, in practice, this really isn't much of an issue. Your are not going to be firing a complete "magazines" worth of BBs in one go. Couple reasons; (1) With say a 2" elbow the gun will hold a thousand or so BB if not more. (2) you won't hit squat firing that way. (3) After the first couple hundred BBs the air supply will probably be too depleted to give decent muzzle velocities. BBMGs should be fired just like a real machine gun, in short controlled bursts.

The needed pressure rating of the PVC parts downstream of the trigger is kind of a trick question. When firing normally nothing downstream of the trigger is subjected to pressure above about 20 PSI or so. It doesn't really matter if you air supply is at 100 PSI or 1000 PSI, the gun is still only operating at 20 or so PSI. So, in normal operation just about any rigid pipe will work.

To be safe, you really should design any gun to be able to withstand having a round jammed in the barrel. That means a typical BBMG should be designed to better than 120 PSIG (typical shop compressor). If you are using a higher pressure source then the gun should be designed to whatever the max pressure is of that source.

Pressure rated PVC in diamters up to at least 4" is rated at greater than 200 PSIG so it'll be fine with a standard shop compressor as the air supply.

Actually, in practice, this really isn't much of an issue. Your are not going to be firing a complete "magazines" worth of BBs in one go. Couple reasons; (1) With say a 2" elbow the gun will hold a thousand or so BB if not more. (2) you won't hit squat firing that way. (3) After the first couple hundred BBs the air supply will probably be too depleted to give decent muzzle velocities. BBMGs should be fired just like a real machine gun, in short controlled bursts.

The needed pressure rating of the PVC parts downstream of the trigger is kind of a trick question. When firing normally nothing downstream of the trigger is subjected to pressure above about 20 PSI or so. It doesn't really matter if you air supply is at 100 PSI or 1000 PSI, the gun is still only operating at 20 or so PSI. So, in normal operation just about any rigid pipe will work.

To be safe, you really should design any gun to be able to withstand having a round jammed in the barrel. That means a typical BBMG should be designed to better than 120 PSIG (typical shop compressor). If you are using a higher pressure source then the gun should be designed to whatever the max pressure is of that source.

Pressure rated PVC in diamters up to at least 4" is rated at greater than 200 PSIG so it'll be fine with a standard shop compressor as the air supply.