First of all, that's not what you normally say. Secondly the first two designs doesn't offer higher muzzle energy than the third one (the one with a detent)I'm not too concerned about being economical with airflow, rather optimising muzzle energy

Detent is a detent - you get - let say 500 psi as opposed to roughly 40 psiLooking at the global picture, note that eliminating the detent increases rate of fire, meaning a given target will require a shorter burst (in terms of firing time) to be destroyed, so you're still saving gas

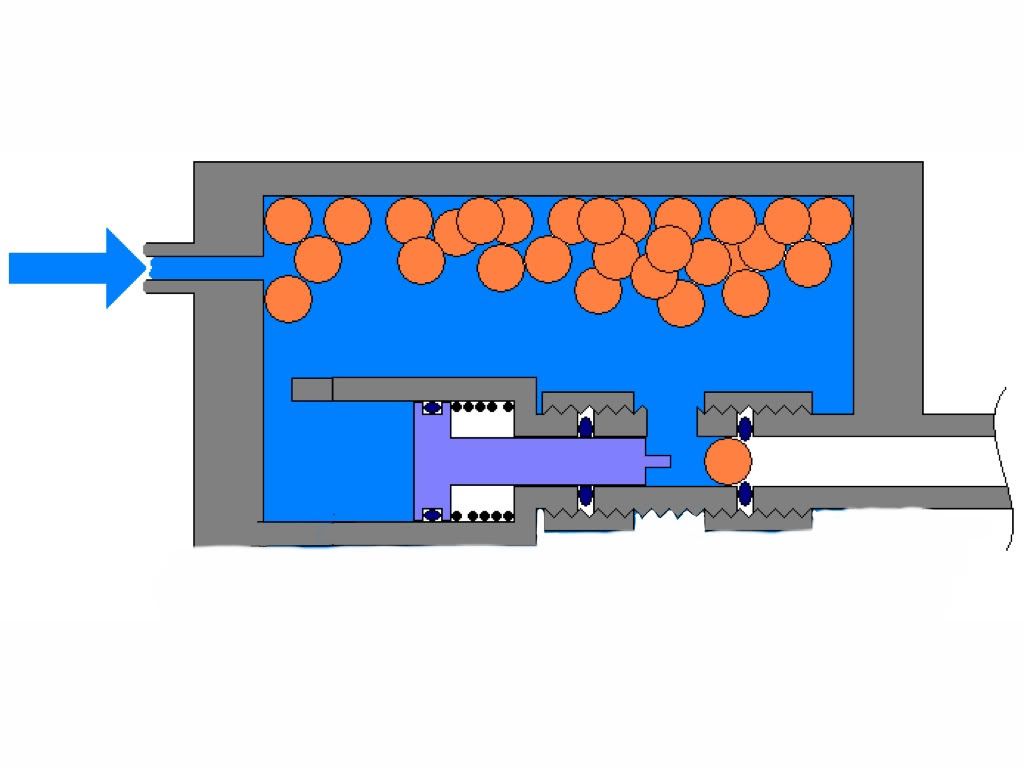

Sure the chamber is pressurised when you open the valve. However, the problem here is the delay between openning the valve and the time when the first bb enters the barrel... I have no idea how to calculate or measure that but the pressure will drop

For me it seems you're trying to reinvent the wheel... nope that's not the right term. You designed a gun that is more like a typical piston valve pneumatic rather than BBMG.

You do know that you might as well use an airsoft hopup unit?

The problem is see here is shi### performance of 1mm ammo... You might not be able to judge the performance of the gun due to that and its scale...I need a "sandblaster" in my armoury though

Choose 6mm (or at least 4.5mm)... build a couple of prototypes and compare their performance.