Page 1 of 6

valveless pellet gun

Posted: Thu Jun 21, 2007 11:19 pm

by jackssmirkingrevenge

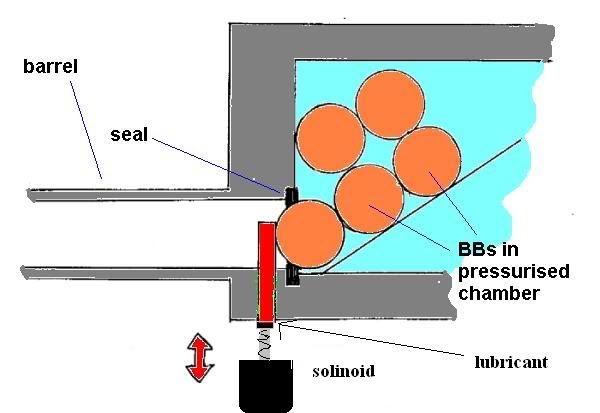

This is an idea I had a while back, which was to dispense with the valve altogether and use the projectile to seal the air chamber, locked in place until it was ready to fire. This would be to all intents and purposes the most effective "valve"

happy red? :p I could think of.

The prototype I actually made had a bolt as a projectile stopper and used 0.22 airgun pellets which gave a good seal on the barrel. The performance however wasn't any better than my mini-piston designs so I shelved the idea as not offering sufficient benefits to warrant the awkward method of operation.

The disadvantage is that you need a projectile that's a 100% airtight fit in the breech, which also has to be of strong enough construction to retain the pressure behind it without collapsing. Still, for those seeking ultimate performance, it might be a workable idea.

For more detailed information on using epoxy, check out the how-tos

here and

here.

Posted: Thu Jun 21, 2007 11:24 pm

by Redcoat

bravo jack, your ideas keep on comng and there always good.I never would have thought of that.That is a good idea maybe for a sniper?

A one shot pistol is pretty annoying (in my books).

Posted: Thu Jun 21, 2007 11:25 pm

by rednecktatertosser

So a valveless gun with the most effective valve you could think of? That made me laugh.

But in all seriousness that is a really good idea. I might just make one this weekend... Providing I find money.

Posted: Thu Jun 21, 2007 11:26 pm

by noname

Knowing you and your epoxy skillz, I think you could make it. Good luck. What kind of projectiles do you have in mind, seeing as they need to seal?

Posted: Thu Jun 21, 2007 11:26 pm

by hi

i think you would have to pull the trigger fairly fast, but it should work, if you can ge it to seal.

Posted: Thu Jun 21, 2007 11:37 pm

by jackssmirkingrevenge

sorry guys but I pressed the "submit" button too early (d'oh!) I actually made a prototype of this, check the edited post

Posted: Thu Jun 21, 2007 11:39 pm

by Velocity

Its like a burst disk on steroids! (not really?)

Nice design here... I am surprised that you were able to get it to seal.

It would be interesting to compare this to a burst disk gun of similar size.

Posted: Thu Jun 21, 2007 11:40 pm

by rednecktatertosser

well another one of your wonderful innovations has been put into my "stuff to build" file in my favorites. once again good job jack, like usual.

Posted: Thu Jun 21, 2007 11:40 pm

by jackssmirkingrevenge

rmich732 wrote:Nice design here... I am surprised that you were able to get it to seal.

It sealed easily without any rubber because the soft lead skirt of the pellet "inflates" and seals agaisnt the barrel. This is after all the same way that brass cartridges seal the propellant casses inside firearms.

Posted: Thu Jun 21, 2007 11:44 pm

by rednecktatertosser

AH so it works off the pricipal of grease seals on a car axle, where its cupped to one side, the side it seals so that it helps hold pressure. thats ingenious.

Posted: Fri Jun 22, 2007 1:36 am

by shud_b_rite

I like your chamber. Where did you get it? Or how did you make it?

Posted: Fri Jun 22, 2007 1:51 am

by FreakyShotGlass

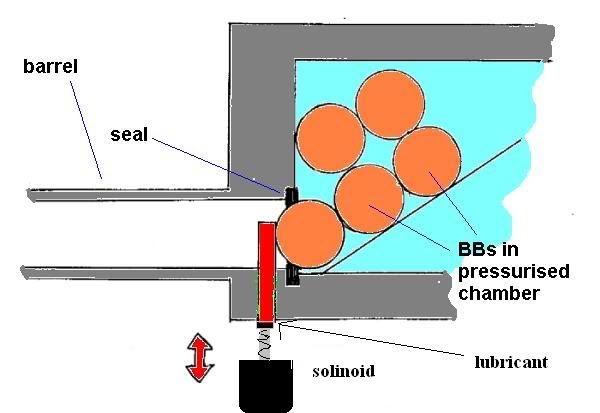

You could use a solenoid to hold back the projectile and then apply a current and the solenoid would activate and release the projectile.

Posted: Fri Jun 22, 2007 2:16 am

by jackssmirkingrevenge

shud_b_rite wrote:I like your chamber. Where did you get it? Or how did you make it?

I made it myself, as per attached diagram.

You could use a solenoid to hold back the projectile and then apply a current and the solenoid would activate and release the projectile.

You'll need a pretty hefty solenoid to achieve that, for a 3/4" barrel at 100 psi it'll have to hold a force of 44 lbs.

Posted: Fri Jun 22, 2007 8:11 am

by potatoflinger

That's a great idea, but wouldn't the pellets wear down the barrel after a while, since they expand to fit the barrel perfectly? It seems like they would scrape the sides the whole way down the barrel.

Posted: Fri Jun 22, 2007 8:34 am

by lukemc

jackssmirkingrevenge wrote:

You could use a solenoid to hold back the projectile and then apply a current and the solenoid would activate and release the projectile.

You'll need a pretty hefty solenoid to achieve that, for a 3/4" barrel at 100 psi it'll have to hold a force of 44 lbs.

what if you made it like this the solenoid wouldnt have to direcly hold back the pressure