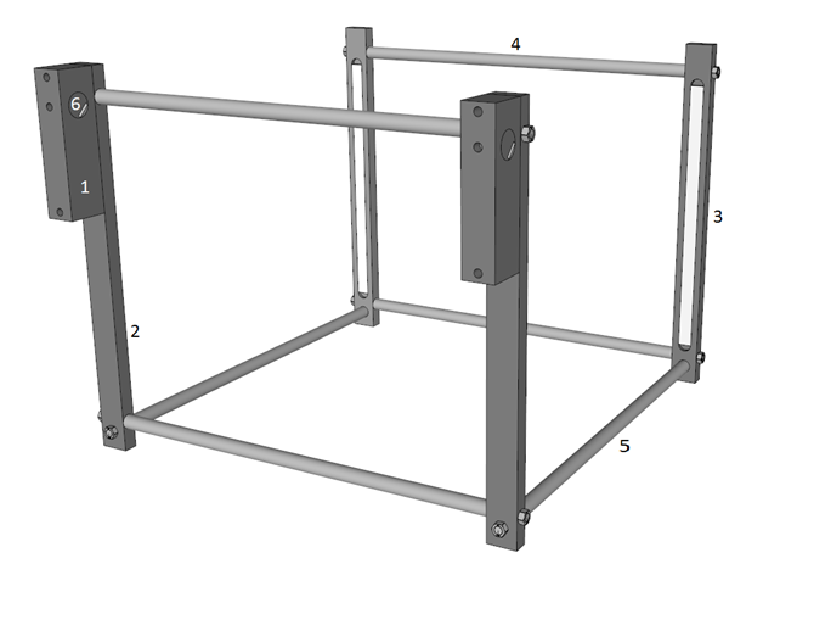

It all started 6 months ago with me choosing the project "Microcontroller based projectile speed measurement". The first thing on the list was designing a frame that would hold two pairs of light sources and sensors at a precise distance from each other. After many design changes I've come up with this:

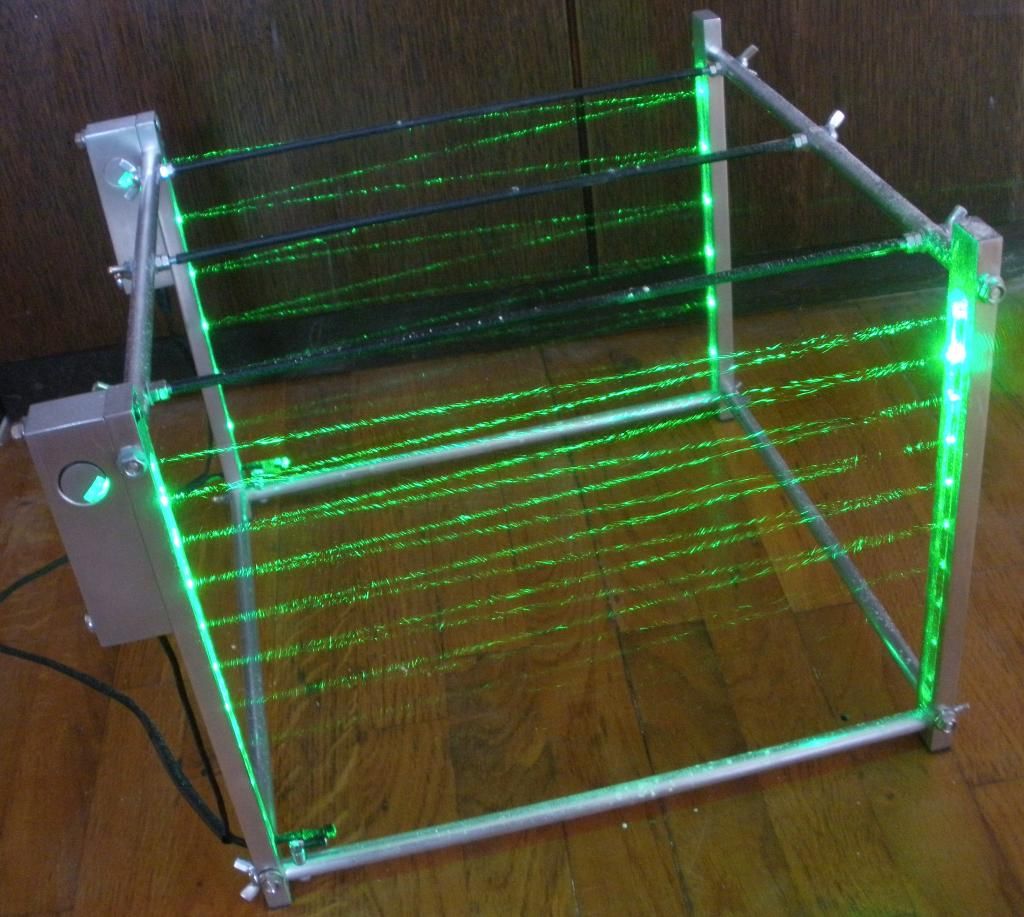

It consists of 6 spacing elements (5,4), 4 mirror housings (3), 2 laser module housings(1) and 2 adjustable mirrors (6). It holds two pairs of mirrors perfectly parallel to each other so a laser beam could bounce a few dozen times inside the 20x30cm area. The angle of the laser beam can be adjusted, thus the number of reflections can be changed depending on the diameter of the projectile. The BPW-34 photodiodes are held in an adjustable fixture on the spacing element, below the laser module housings.

For the project I chose AT89S8253 microcontroller since thats what we mostly used at school. Its running at 24MHz which gives me a time measurement resolution of 500ns. When the laser is directed onto the sensor, the photodiode output voltage is only about .4V which is not enough to set the microcontroller input to "1" so I had to use a LM319N high speed voltage comparator in a basic photo detector circuit. On its output I can get 3.5V when the laser is on the photodiode, and 0.8V when the laser beam is broken. This is just within specs for the AT89S8253 logic "0" and "1" voltage levels. It enabled me to program the microcontroller to check only two ports for the time measurement. Once the first laser beam is brkoen, the microcontroller starts a timer. When the second laser beam is broken, it stops the timer. Then it automatically calculates the speed v=0.3/t (sensors are .3m apart). After that it freezes the result for 1 sec so anything flying behind the projectile won't break the first laser beam and restart the measuring sequence, erasing the previous result. After that 1 sec the measurement can be repeated or the result can be displayed in fps or km/h. Power source is a Leoch hermetically sealed 12V lead acid battery regulated down to 5V with a LM317 voltage regulator.

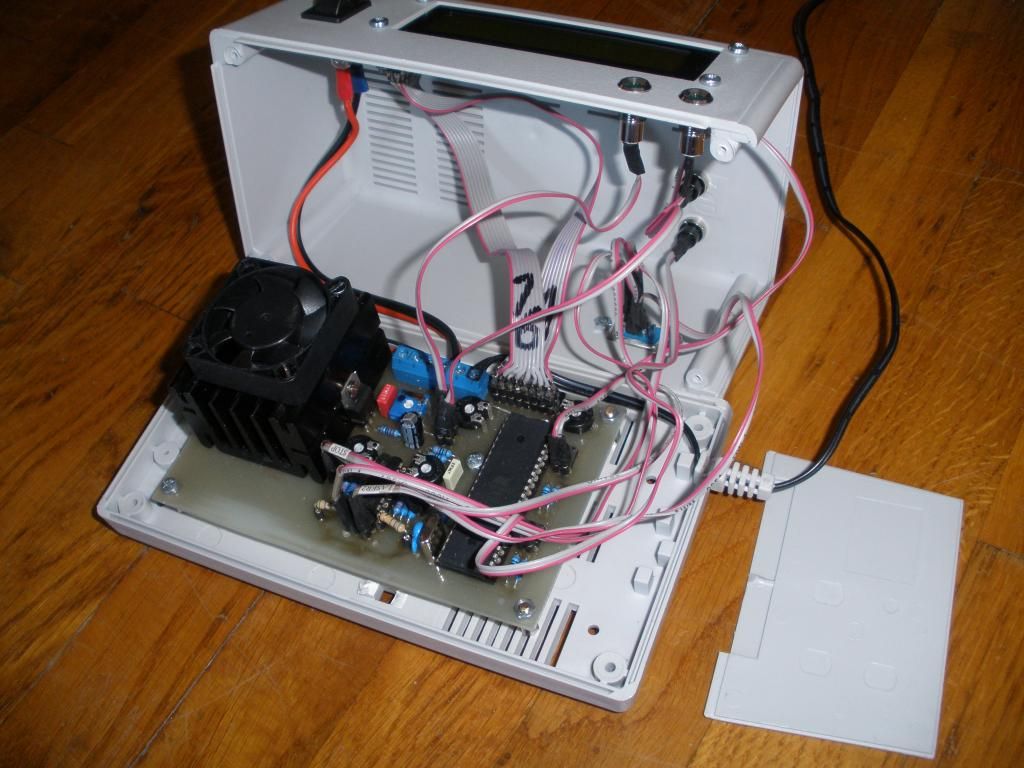

Here is the inside of the control box:

The two lasers and photodiodes mounted in the aluminum frame connect to the control box with a VGA cable. It has just enough wires to connect everything I need but unfortunately it left a mess inside. On the front of the control box there is a simple power switch. To the right of that is the 20x2 LCD. Under the LCD are two status LEDs. Once the front laser is directed onto the start photodiode, the left green LED will turn on. The same goes for the rear laser/stop photodiode and right LED.

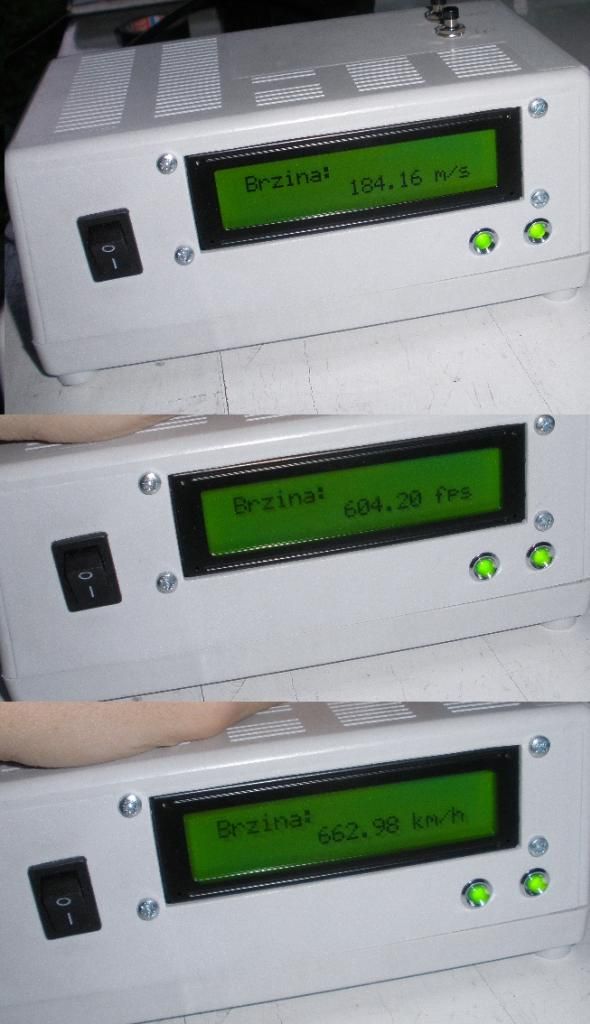

On top of the control box are two buttons which allow for unit conversion. The default is m/s but pressing the appropriate button will display the speed in fps or km/h. This was the 10th measurement at 10 bar: (PS: "Brzina" is "Speed" in Croatian

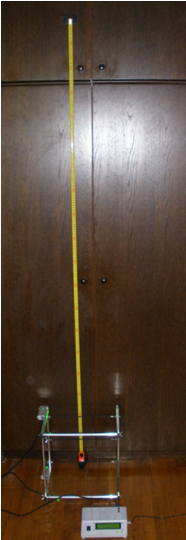

I don't have a commercial chronograph to compare the results but I did run a couple of tests. For the first test I've calculated the speed at which a .50 cal paintball will hit the ground after falling from a height of 1.8m. Its around 5.78m/s. Then I measured the speed of the same scenario with my chronograph. After 10 measurements the average measured speed was 5.85m/s which turned out to be an error of about 1%. Heres the setup:

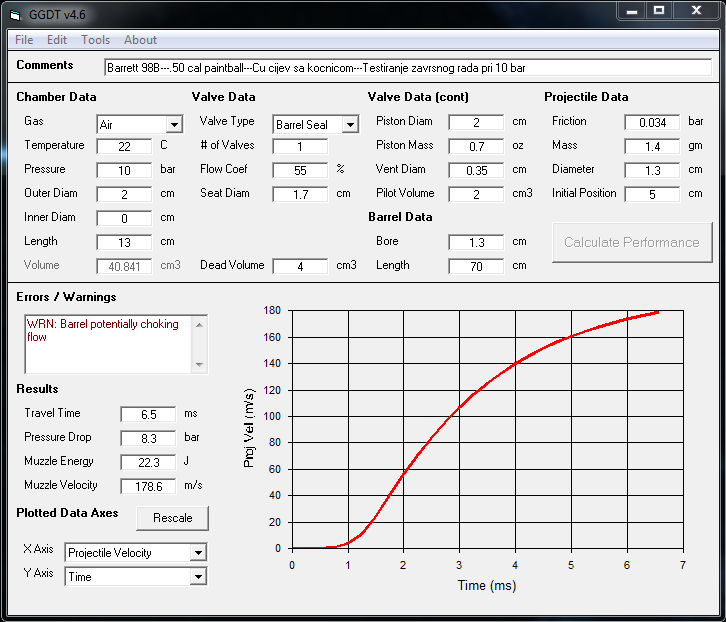

For the second test I've fired 10 .50 cal paintballs from my Barret 98b at a chamber pressure of 10 bar.

The average measured speed was 178.53m/s. The only thing I could compare this to was GGDT. I'm just not 100% certain of the dead volume value since I didn't really measure the volume of the 5cm long safety switch between the barrel and QEV. Even if this value is incorrect by a fraction, the results are still surprising.

GGDT estimates a speed of 178.6m/s which would mean the chronograph accuracy is 99.96%. I know that speed is just an estimate and I'm probably introducing an error with my inconsistent reading of the tiny pressure gauge and really cheap ammunition but these tests at least proved the chronograph is not spitting out complete nonsense. The real test will come when I get to compare it directly to a commercially made chronograph. The only problem is finding somebody willing to do the experiment.