I would recommend using a 3/4" QEV (quick exhaust valve) and another 3way-2position valve (sleeve valves are popular choices) instead of a sprinkler valve and modded blowgun due to the poor flow and slow fill rates, I choose these valves because I already owned them and I'm very reluctant to order parts online (note: besides parts I already owned the deus ex machina only cost me $20 to make)

I will not go into detail about the specific assembly of the pneumatics in the deus ex machina, the specific details should be determined based on one's aesthetic preferences and available parts

the rest of this HOW-TO will focus on the construction of the bolt action cartridge feeding and ejecting system

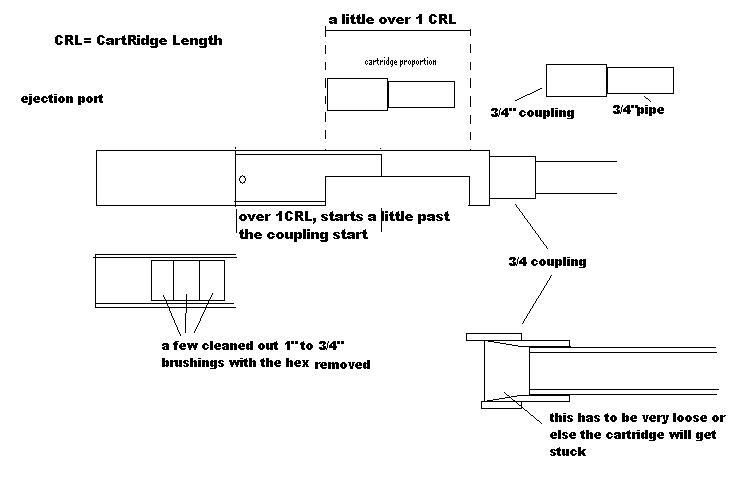

edit:warning the design in this how-to takes advantage of various pipe and coupler sleeving tricks, for example most 3/4" couplers are relatively smooth with the exception of one or two small bulges they can slide into most 1" pvc, if the they require a significant amount of sanding or lathe work to make the coupler fit then this approach is not worth attempting, unfortunately there is no specific standard for the outer diameters of couplers or the inner diameters of pvc pipe so please c

material:

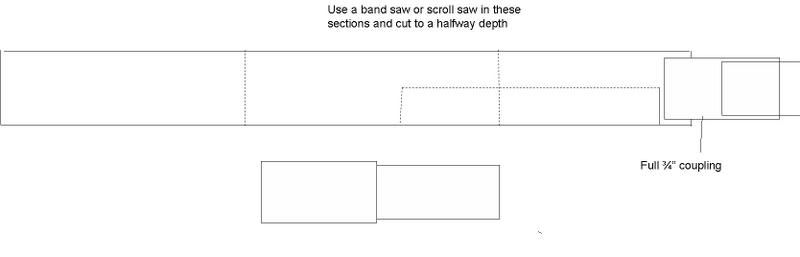

bandsaw or scroll saw

dremel or stick file

router (for bolt action slot or else you'll have to find another way)

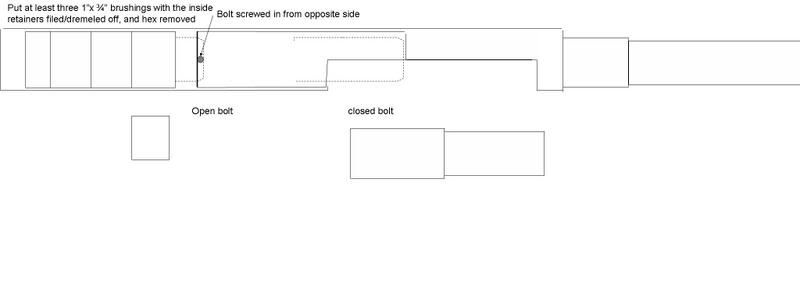

a threaded bolt to use as a bolt handle and one to be the ejector

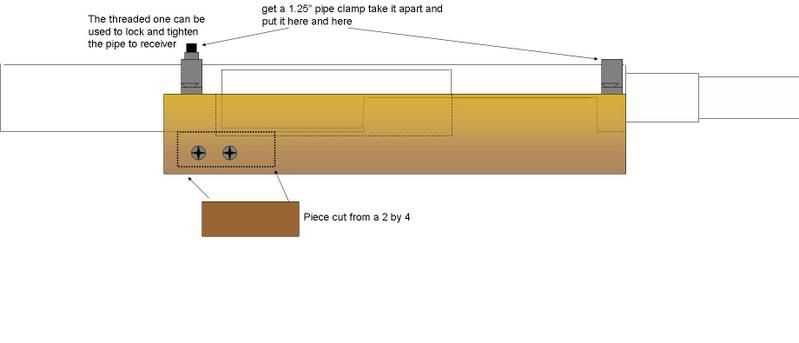

1.25pvc

3/4" pvc

3/4" couplings you will need plenty of these based on how many cartridges you want

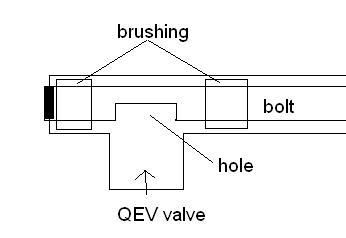

3+ 3/4"x1" brushings

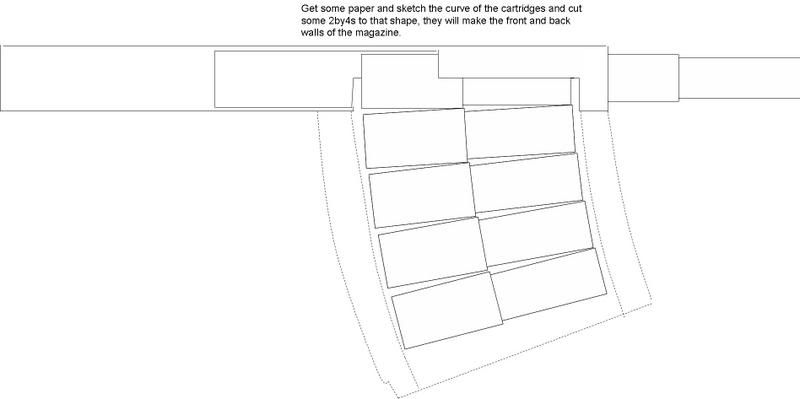

the short depth of the 2x4 are almost perfect for these shells

the side (left and right) walls will be made from thin plexiglass, and the magazine spring should be made from music wire

important info the cartridge ejection system works by having the bolt on the oposite side hit the rim of the cartridge causing it to flick off and out the ejection port, the secret to make this work is to make the front coupling very losess and the bolt pretty tighter but hang on by half a centimeter so when you first use this you will have to use keep on ajusting the friction in the front coupling and bolt, I recomend grinding the front with somthing smooth or use a polishing brush bit on your dremel, and for the bolt I found that a preparing a drop of JB weld on some paper then smearing it all over the front evenly to create a new layer works pretty well

NEW UPDATE AN ANIMATED DIAGRAM

really the new cartridge should instantly appear because this is magazine fed, but I forgot and I already made the frames without it by the time I realized

here a video of my deus ex machina which is diffrent only in terms of sizes and fittings used to accomplish the task this way involves lots of grinding down at the belt sander but it includes all the basic parts,

http://s30.photobucket.com/albums/c328/ ... ¤t=D SCF0890.flv

http://s30.photobucket.com/albums/c328/ ... ¤t=D SCF0890.flvI used an original blowgun mod to fill and actuate the valve

http://www.spudfiles.com/forums/semi-blowgun-t6877.html

here all the other threads about the deus ex machina

http://www.spudfiles.com/forums/deus-ex ... t7723.html

http://www.spudfiles.com/forums/deus-ex ... t7864.html

http://www.spudfiles.com/forums/deus-ex ... t8418.html