Auto piston valve + realoading system (BB cannon example)

Posted: Fri Oct 26, 2007 1:07 pm

Ok, first off, the automatic piston valve:

It uses the pop-off valve idea, but in a chamber filling version.

A spring keeps the piston(or membrane) foreward while air leaks in and the pop-off valve dumps the air in the pilot port at the set pressure.

It has a slower cycle than some of the other full auto or pulsed air design but is more efficiant than the normal pop-off valve design because of the smaller pilot volume and less air is lost while the valve reseals( and it is lost down the barrel instead, making a nicer vapour trail ? )

)

For use with the auto piston valve, or any other full or semi-auto system, this realoading system, uses a small pneumatic ram connected to the chamber.

The ammo is loaded between shots, possibly making it more reliable than

most blow forward and blowback designs.

I can also be combined with a simple shell ejecting system.

The bolt only moves back once the pressure in the chamber has dropped enough so there a fewer leaks.

There is also less obstruction to the air flow, the smallest inside diametre in this system is the same size as the ammo; so better flow and less resitance and therefore less chance of it blowing apart because of the amount the air dumped by a good piston valve.

It also enables one to add moving exterior parts (such as a cocking lever ?) making the action look like gas blowback systems.

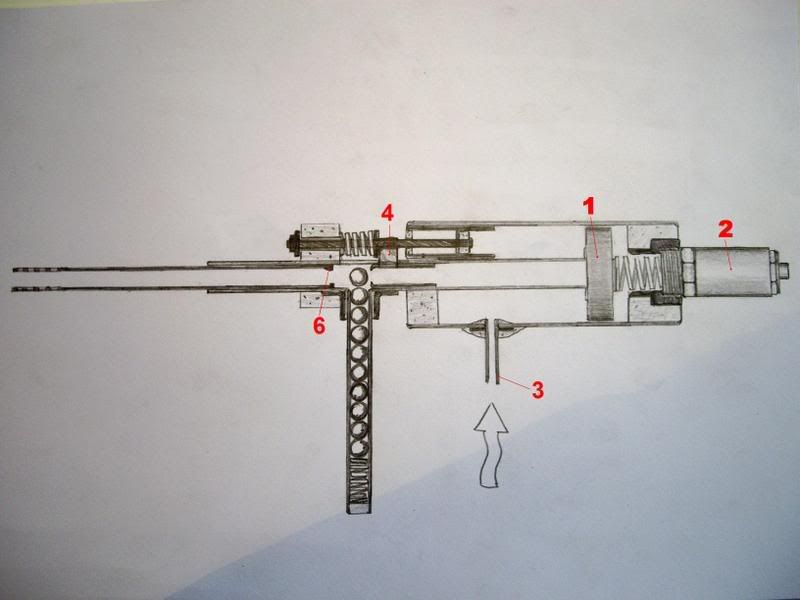

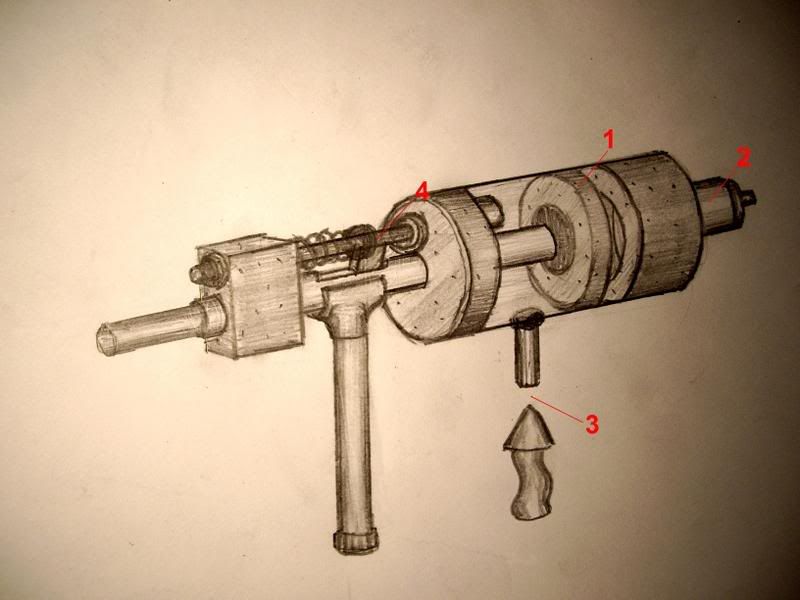

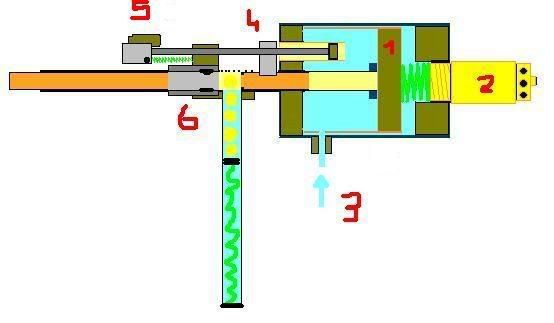

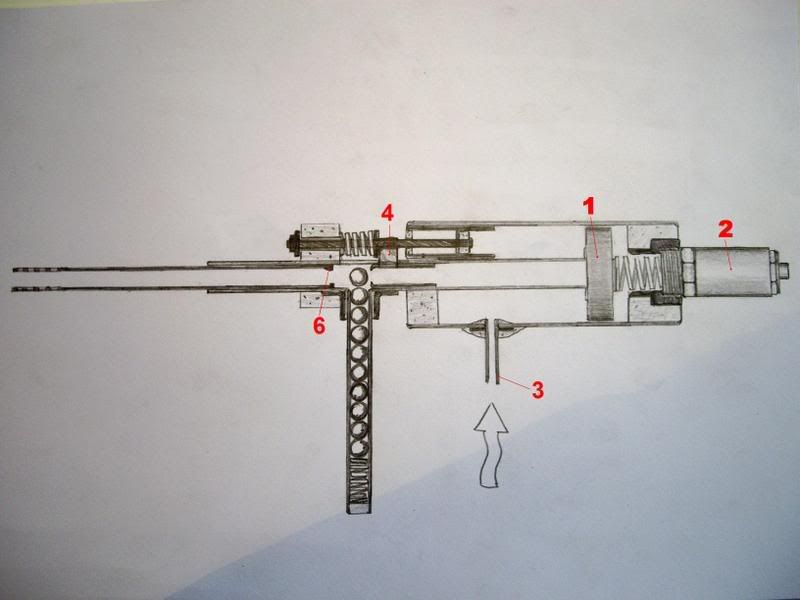

Ok here are the pictures:

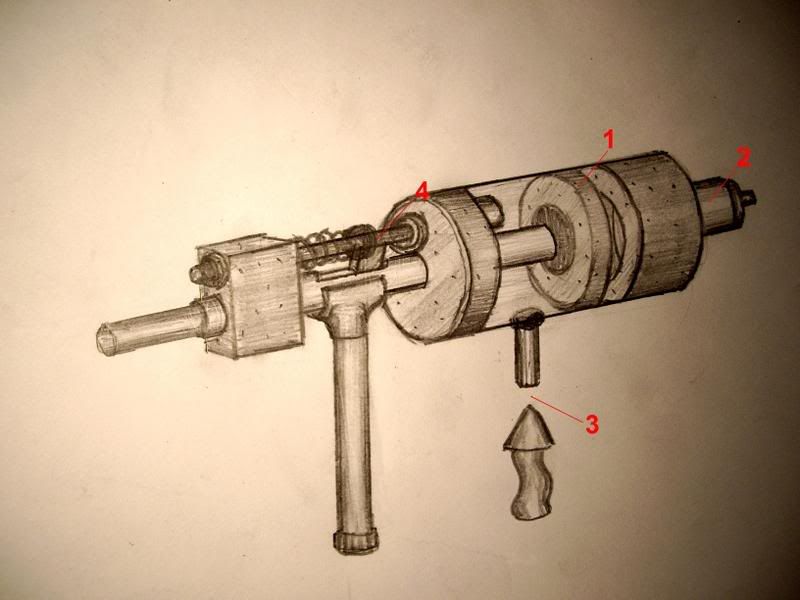

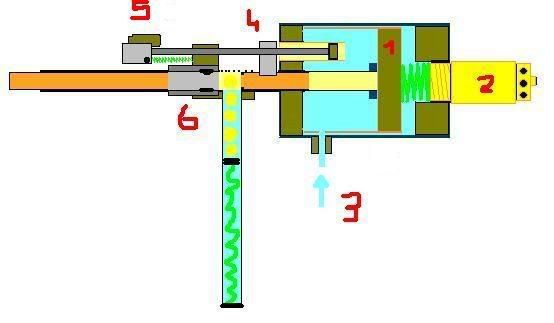

1- Is a basic piston, but it has to let air bleed from the chamber to the pilot port. A few simple modifications could reduce air loss some more.

2- Is a pop-off valve, set to what ever pressure is wanted. (A 70psi pop-off and a ~10cm barrel is all that would be needed for airsoft...)

3- Is connected to any kind of basic valve (ball valve, blow gun, slide valve...)

A regulated air/gas source would be best, a bigger chamber with a regulator, a comrpessor, HPA, CO2 or any regulated gas.

4- Is a small part connecting the inner loading tube to the ram. The loading tube is just the same size as the one used for the barrel, if cut with a pipe cutter leave the end bend inwards for better loading.

5- Is a cocking handle but could be anything that need to move after a shot.

6- Is optional, but usefull. It's some kind of hop-up or o-ring to stop the BBs from rolling out of the barrel and/or give spin to the projectile.

This design is good for people looking for a slower rate of fire that Strafers but more powerfull, consuming less air and with a mechanical action and sound. (closer to the Dakka dakka anyway)

I might build this one day but I don't have the time at the moment, it's posted on here so anyone who would like to try it out can.

I have started a larger calibre semi-auto version.

It shoots ~14mm (.55cal) epoxy rifled bullets. (or anything that size...)

It runs with a 3/4" QEV so the ram isn't embeded, it is jsut part of the chamber.

It uses the pop-off valve idea, but in a chamber filling version.

A spring keeps the piston(or membrane) foreward while air leaks in and the pop-off valve dumps the air in the pilot port at the set pressure.

It has a slower cycle than some of the other full auto or pulsed air design but is more efficiant than the normal pop-off valve design because of the smaller pilot volume and less air is lost while the valve reseals( and it is lost down the barrel instead, making a nicer vapour trail ?

For use with the auto piston valve, or any other full or semi-auto system, this realoading system, uses a small pneumatic ram connected to the chamber.

The ammo is loaded between shots, possibly making it more reliable than

most blow forward and blowback designs.

I can also be combined with a simple shell ejecting system.

The bolt only moves back once the pressure in the chamber has dropped enough so there a fewer leaks.

There is also less obstruction to the air flow, the smallest inside diametre in this system is the same size as the ammo; so better flow and less resitance and therefore less chance of it blowing apart because of the amount the air dumped by a good piston valve.

It also enables one to add moving exterior parts (such as a cocking lever ?) making the action look like gas blowback systems.

Ok here are the pictures:

1- Is a basic piston, but it has to let air bleed from the chamber to the pilot port. A few simple modifications could reduce air loss some more.

2- Is a pop-off valve, set to what ever pressure is wanted. (A 70psi pop-off and a ~10cm barrel is all that would be needed for airsoft...)

3- Is connected to any kind of basic valve (ball valve, blow gun, slide valve...)

A regulated air/gas source would be best, a bigger chamber with a regulator, a comrpessor, HPA, CO2 or any regulated gas.

4- Is a small part connecting the inner loading tube to the ram. The loading tube is just the same size as the one used for the barrel, if cut with a pipe cutter leave the end bend inwards for better loading.

5- Is a cocking handle but could be anything that need to move after a shot.

6- Is optional, but usefull. It's some kind of hop-up or o-ring to stop the BBs from rolling out of the barrel and/or give spin to the projectile.

This design is good for people looking for a slower rate of fire that Strafers but more powerfull, consuming less air and with a mechanical action and sound. (closer to the Dakka dakka anyway)

I might build this one day but I don't have the time at the moment, it's posted on here so anyone who would like to try it out can.

I have started a larger calibre semi-auto version.

It shoots ~14mm (.55cal) epoxy rifled bullets. (or anything that size...)

It runs with a 3/4" QEV so the ram isn't embeded, it is jsut part of the chamber.