Page 1 of 3

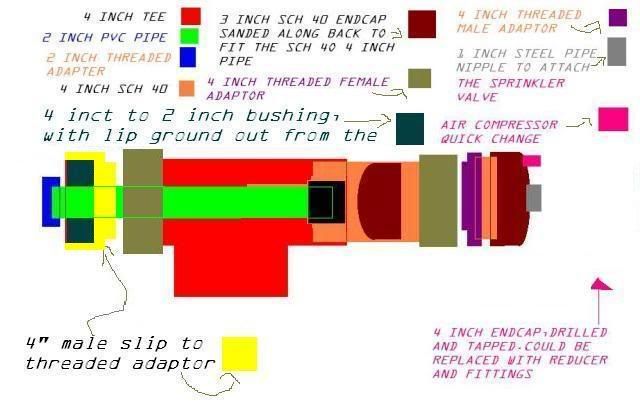

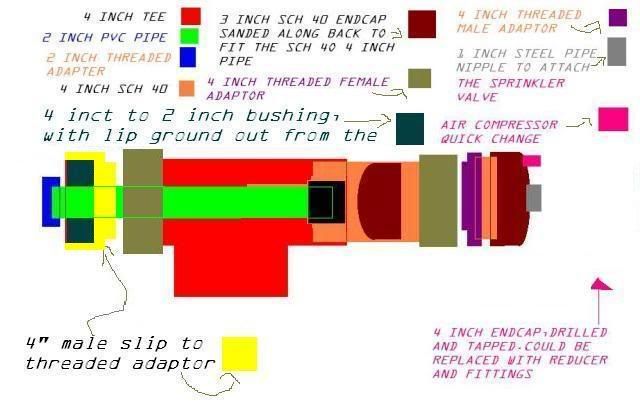

No-tool 4" piston valve

Posted: Sat Mar 25, 2006 8:51 pm

by schmanman

this is a cheap and easy to make,and powerful valve. it opens quicker than the supah valve,too. to see it better,copy it and paste it on word,or a program where you can enlarge it and/or print it out as a guide when building or buying parts to make it.for the 4 inch sch 40 tee,go to

http://www.sprinkler.com

the 3 inch sch 40 endcap piston was sanded around the back,where you will find small ridges of extra pvc from when it was injection molded. buy the smoothest endcap and rubber coupler you can find

[NOTE : USE ALL SCHEDULE 40

Posted: Sat Mar 25, 2006 11:36 pm

by Atlantis

This is basically a generic PVC parts piston. I have a feeling you stole these plans, or just modified some existing plans. By the way, THE GIANT RED LETTERS ARE GETTING REALLY ANNOYING! I think quite a few people do not appreciate your font.

Posted: Sun Mar 26, 2006 8:41 am

by schmanman

yeah,I'm changing the font. but,no, I did not steal or modify existing plans.search arround,because you wont find it anywhere else .I drew this up on paint yesterday.I didn't know anyting about piston valves,so I did a couple weeks of reaserch to figure out how they work.iI combined the parts from alot of different piston valves into one valve,and came up with a couple things myself.

Posted: Thu Mar 30, 2006 8:01 am

by spud freak

nice valve.i luv the simple pistin design.im going to buildit but not in a tee,ina sholder rocket launcher.i cant find this design anywhere else,atlantis.

Posted: Thu Mar 30, 2006 5:27 pm

by spudshot

how do you know its faster than a supah valve? it doesnt seem safe to have a 1" hole tapped in the center of a cap. he didnt steal the plans, he just adapted someone else's idea of using a fernco quick coupler as the sealing face.

Posted: Fri Mar 31, 2006 10:09 am

by Atlantis

Sorry for being so cynical, I've just seen pistons made out of 3" endcaps before, they fit in 4" pipe.

Posted: Fri Mar 31, 2006 9:52 pm

by schmanman

it's an inhernt property of barrel-sealing piston valves, and the sprinkler valve helps a ton. Cynical,ha,I sounded like I was braging.The font upset a lot of people,I just wanted feedback because I was excided and it got peoples attention.I did'nt know people had used 3 inch couplers or endcaps as pistons or rubber couplers as the piston seating surface before

the pipe tapped into the endcap also has half a steel union inside,so even if the threads go,the pipe does not shoot out.I have fireing box that contains all the batteies,switches,buttons.It has a 15 foot cord,so I stand behind and to the side of the launcher,so nothing could happen. And,I never get the gun above 80,because at that pressure,It blows a 3 inch section of 1 1/2 inch pvc filled with sand through a carhood from 80 feet away,and keeps going

Posted: Thu Dec 14, 2006 1:26 am

by Trey33088

I'm a bit of a newb, so I don't fully understand how this valve works. It's right up my alley b/c I've been looking for an off-the-shelf-parts piston valve. How does particular valve work? Whats the black thing in the pic, and whats the 2 inch pipe for?

Posted: Thu Dec 14, 2006 3:37 pm

by schmanman

well, for one, here's a better, more updated version.

the black thing is a 2" fernco rubber coupler, and the 2" pipe goes to the barrel. It is what the piston seals up against, check the wiki for an explanation.

Click to view full-size

Posted: Sun Dec 17, 2006 9:23 pm

by Trey33088

Okay, so I've been studying up on this idea for a while now, and I've got a few ideas I'd thought I'd share. sry, no pics yet, but they'll be here soon.

1. On the left side of the valve pictured, instead of the male and female connections, a 4 inch to 2 inch bushing is used directly in the T. the male and female are great for breaking the valve down, but they just add to cost.

2. Instead of the male and female on the back, a wastegate is used on the end with and endcap. you can plumb a quick connect directly into the endcap square.

okay, now the questions lol

1. instead of 2 inch PVC, would 3 inch be worth trying? the fittings would have to be adjusted, but i was more worried about the gap in between the 3 and 4 inch pipe on the inside. its narrow compared to the 2 inch pipe, so how much do yall think that would affect performance? would it bottleneck too bad?

the 3 inch rubber bushing would seal against the endcap much much better than the 2 inch, so i was wanna now if its worth doing.

2. after reaming out the 4-2 bushing, would pvc cement seal it off well enough when you slide the 2 inch pipe through it?

3. what do ya'll think would be a better way to return the piston to the closed position: a compression spring behind it, or two smaller extension springs screwed into the inside of the 4" pipe and the cap so that as it opens the springs stretch and pull it closed when the pressure is low enough.

4. any ideas as to a good bumper behind the piston? i was thinking about changing my earlier idea of mounting a wastegate directly to the T and using a piece of 4 inch pipe mounted inside the T, with a 3" rubber donut (which fits perfectly inside 4 inch pipe) inside the pipe, and the wastegate mounted on the other end of the shor piece of 4 inch pipe. that way when the valve slams back, it hits about a 1/4 inch of rubber donut along the edge and stops without hitting anything else.

5. (last one for now) i should grease the piston with something, right? and i have to drill equalizing holes into it also, right? sry i think i should, but im new so im lookin for reinforcement lol.

thanks guys.

Trey

Posted: Tue Dec 19, 2006 6:33 am

by schmanman

well, you want the fittings for breaking it down, because if the rubber coupler splits, you cannot access the hose clamps, and you have to cut the valve off, and rebuild it from scratch, totally over.I found out the hard way.

you could use three inch, but ti is gonna be a tight fit. gotta go, answer the rest later.

Posted: Tue Dec 19, 2006 1:43 pm

by Trey33088

Well, by using a regular old wastegate you can still open the rear of the valve. Then again, your right about the clamp... i wouldnt be able to tighten it. I'll go put it together at the hardware store later and post any probs ive had before i break down and buy everything. thanks for the help.

Posted: Tue Dec 19, 2006 3:22 pm

by schmanman

make sure to use pressure rated nfs-pw parts.

Posted: Tue Dec 19, 2006 7:07 pm

by Trey33088

I got to thinking about some parts i found at Home Depot the other day. theres a thing called a rubber "donut" that fits inside one size of pipe and allows another to fit inside of it with a decent seal. I was thinking that instead of using a fernco coupler, id just go with 3 inch PVC and shove the donut in the end. a 2 inch pipe would usually slide inside the donut, but since that would give the inside diameter of the donut nearly the same size as the outside diameter of 2" pvc, it'll seal just as well as a 2" coupler. the difference would be that theres no chance of it cracking b/c is slides inside the end of the 3 inch barrel, with an outer rubber lip on the end to keep it from sliding down. so the piston should be able to seal nicely up against the lip and wont expand and break the rubber.

Finally built my valve! Almost complete

Posted: Sat Apr 07, 2007 12:19 am

by Trey33088

Wow... it's been a while since I've checked in...

Anyway, I finally got enough extra cash to pick up some parts to build this valve, but while looking I change everything up to make it a hell of a lot more efficient lol.

First of all, I fit the whole thing in a 3x3x2 inch tee. I had to use a 2 inch top because with a 3 inch, whenever the end cap hits the rubber donut, theres a huge hole behind it caused by the curve of the pipe. a 2inch however fits perfect.

secondly, i made the valve a full 4 inch valve by allow the air to never narrow more than the inside of the donut. if you notice, i have a 4x3 inch flush reducer, but thats b/c i was a bit indescisive. instead, im going to use another threaded adapter so that i can use interchangeable barrelss, and a total 4 inch barrel without the air ever narrowing down to 3 inches, as it is now.

in the rear, i still havent decide quite how to trigger it, but im using an endcap so that if i ever need to replace the endcap/piston, it'll be easy. what im thinking about doing is just tapping a quick connect towards the side of the endcap, and then porting a 1 inch hole right on the square nob and attaching a modified sprinkler valve.

all the pieces

the rubber donut inside the tee

shot from the top so you can see how far it goes

the 4x3 flush reducer. not gonna get glued in though... im gonna just put a threaded adapter so that i can put interchangeable barrels, including a complete 4 inch barrel, on without the air ever narrowing more than the inside of the donut.

shot from the end.

theres the piston on the inside, butted against the donut.

and theres the gap.

from the back

with the adapter on.

and finally the endcap.

ya'll let me know what you think, im still a newb, so im willing to take all comments, tips, insights, ideas, criticisms, whatever you got.