machined APFSDS projectiles

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 581 times

- Been thanked: 347 times

I've been having a play with milled collars to turn small masonry nails into stable darts without any modification of the nail itself. In 6mm calibre, a simple airsoft BB serves as a sabot.

Some test firing at 15 metres shows that the projectile is stable and even fired from a low powered small 300 psi pneumatic, can still poke out of the far side of a 3/8" sheet of plywood.

This can be made relatively quickly and cheaply, anyone interested in purchasing such parts?

I'm open to bigger calibres of 1" or so, and would also provide the wadding.

edit: altered the thread title to reflect the content

Some test firing at 15 metres shows that the projectile is stable and even fired from a low powered small 300 psi pneumatic, can still poke out of the far side of a 3/8" sheet of plywood.

This can be made relatively quickly and cheaply, anyone interested in purchasing such parts?

I'm open to bigger calibres of 1" or so, and would also provide the wadding.

edit: altered the thread title to reflect the content

Last edited by jackssmirkingrevenge on Thu Aug 22, 2013 3:10 pm, edited 2 times in total.

hectmarr wrote:You have to make many weapons, because this field is long and short life

Aren't you going to regret that ?This can be made relatively quickly and cheaply, anyone interested in purchasing such parts?

That said, I could use a couple of these when I go back home this Christmas 14mm OD , 4mm ID, I have some tungsten rods that need stabilising

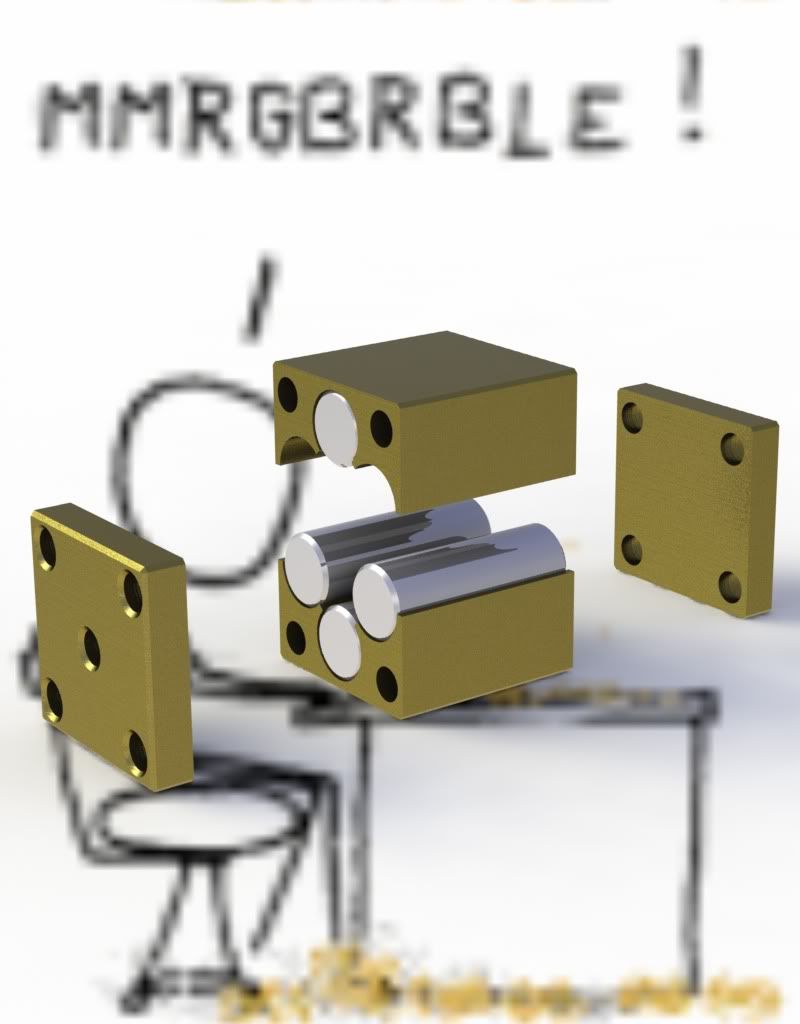

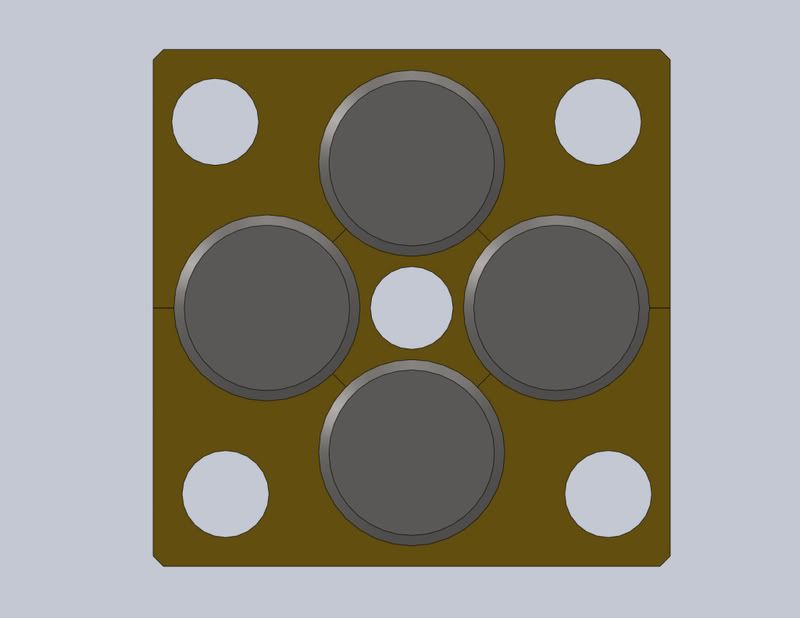

You could quite easily make a mold tool for these. Two machined brass blocks with 4 pins through them and two brass bits to close it off. I'll make a CAD model.

Last edited by al-xg on Wed Nov 09, 2011 2:57 pm, edited 2 times in total.

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

ohh come on al-xg he's going to outsource production to the same guys who mass produce these

to be honest that's how it should be made... mass produced and very cheap

EDIT

PUI

to be honest that's how it should be made... mass produced and very cheap

EDIT

PUI

Children are the future

unless we stop them now

unless we stop them now

- mobile chernobyl

- Corporal 3

- Posts: 759

- Joined: Sun Dec 03, 2006 11:53 am

- Been thanked: 8 times

I'd take some for 1.68" now, and some for 3" in almost a year  Preferably with a pilot hole that can be bored out to the shooter's choosing!

Preferably with a pilot hole that can be bored out to the shooter's choosing!

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 581 times

- Been thanked: 347 times

Indoors or not, these will shatter on impact fired from a reasonably performing launcher so they are single use anyway.al-xg wrote:Aren't you going to regret that ?Unless someone is shooting indoors they're probably going to need a fair quantity of these.

My idea though is not to make an "everyday" projectile but to have something in limited runs for those who want to edge out the performance of their launchers.

This is basically what I'm talking about:

A launcher that could only dent the surface of the target with a fullbore lead projectile at point blank range easily penetrated with a saboted dart.

I'm sure we could work something outThat said, I could use a couple of these when I go back home this Christmas 14mm OD , 4mm ID, I have some tungsten rods that need stabilising

Nice model (background and allYou could quite easily make a mold tool for these. Two machined brass blocks with 4 pins through them and two brass bits to close it off. I'll make a CAD model

to be honest that's how it should be made... mass produced and very cheap

I don't think I could guarantee enough customers to make this a commercially viable option, besides spudders tend to be a tight lot (or toight, depends on where they are

If only you could make them larger than 1.5" or so I'd be a keen bean

This is the reality of the sherline chuck:

It has a clamping range of from 3/32" (2 mm) up to 1-1/2" (38 mm) diameter with the jaws in the normal position. With the jaws in the reversed position, work up to 2-3/4" (70 mm) can be gripped.

Reversing the jaws is a bit of a pain in the arse, but it can be done if it's worth my while.

The other limit (until I inevitably get riser blocks...) is the 1.88"/47mm swing over cross slide - though in reality, using the mill + rotary table, I could go higher - but the lathe is more convinient.

Need to look into the casting options as individually milling larger parts will lead to "miniboy syndrome"...

Preferably with a pilot hole that can be bored out to the shooter's choosing!

Exact barrel and nail dimensions would be required of course for custom jobs.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 581 times

- Been thanked: 347 times

Some footage from behind a 0.4mm thick steel sheet target:

[youtube][/youtube]

First shot is a 1 gram lead pellet, second is a 0.67 gram nail dart.

Nail weighs 0.56g, fins weigh 0.11g, centre of gravity is 14mm from the nose, calculated centre of pressure is 15mm from the nose (25mm overall length)

[youtube][/youtube]

First shot is a 1 gram lead pellet, second is a 0.67 gram nail dart.

Nail weighs 0.56g, fins weigh 0.11g, centre of gravity is 14mm from the nose, calculated centre of pressure is 15mm from the nose (25mm overall length)

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Labtecpower

- Sergeant 3

- Posts: 1297

- Joined: Sat Feb 20, 2010 6:38 am

- Location: Pyongyang

- Has thanked: 5 times

- Been thanked: 13 times

Nice penetration

Did you have something behind the steel plate to protect your camera?

Did you have something behind the steel plate to protect your camera?

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 581 times

- Been thanked: 347 times

The only reason I was comfortable taking the shotLabtecpower wrote:Did you have something behind the steel plate to protect your camera?

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Labtecpower

- Sergeant 3

- Posts: 1297

- Joined: Sat Feb 20, 2010 6:38 am

- Location: Pyongyang

- Has thanked: 5 times

- Been thanked: 13 times

Forgot about that one..

Do you have a purpose for the pistol grip yet?

I might try to shoot a tungsten welding electrode from my hybrid.

Should do some damage

Do you have a purpose for the pistol grip yet?

I might try to shoot a tungsten welding electrode from my hybrid.

Should do some damage

JSR,

Thanks for the plug. In thinking about your fins, you have a milling machine I believe. If you can stand the material on end with maybe a 3 jaw chuck mounted in a rotary table, you could machine these fins with a long small diameter end mill. You can deviate away from the shape a ball end mill creates.

Lest you inject them under pressure, the mold will be a bit difficult to fill.

@al-xg, Nice rendering. Great design, hard to get tapered leading edges on the fins with that. Mike builds 4 sided molds that are locked together to create similar parts.

Concede it would be difficult to do on a manual machine.

USGF

Thanks for the plug. In thinking about your fins, you have a milling machine I believe. If you can stand the material on end with maybe a 3 jaw chuck mounted in a rotary table, you could machine these fins with a long small diameter end mill. You can deviate away from the shape a ball end mill creates.

Lest you inject them under pressure, the mold will be a bit difficult to fill.

@al-xg, Nice rendering. Great design, hard to get tapered leading edges on the fins with that. Mike builds 4 sided molds that are locked together to create similar parts.

Concede it would be difficult to do on a manual machine.

USGF

jsr i was thinking of converting my sherline to cnc then building a abs extruder head like on the makerbot. It would be interchangeable like the normal sherline head, could be a great way to make disposable things like this, just set it printing a set of 25 or so go watch some tv come back to shoot/sell.

I think Im going to get the board from gen 6 reprap and 4 steppers, that way I can have a double use cnc and low quality 3d printer.

I think Im going to get the board from gen 6 reprap and 4 steppers, that way I can have a double use cnc and low quality 3d printer.

Patience is a virtue, get it if you can, seldom in a women, never in a man.

- jackssmirkingrevenge

- Five Star General

- Posts: 26219

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 581 times

- Been thanked: 347 times

It's waiting for a hybrid cartidge I'm happy with.Labtecpower wrote:Do you have a purpose for the pistol grip yet?

Thank you for the housing, expect a lot more dangerous shots in futureThanks for the plug. In thinking about your fins, you have a milling machine I believe. If you can stand the material on end with maybe a 3 jaw chuck mounted in a rotary table, you could machine these fins with a long small diameter end mill. You can deviate away from the shape a ball end mill creates.

Interesting combination, my plan is to go CNC within the next couple of yearsjsr i was thinking of converting my sherline to cnc then building a abs extruder head like on the makerbot . It would be interchangeable like the normal sherline head, could be a great way to make disposable things like this, just set it printing a set of 25 or so go watch some tv come back to shoot/sell.

Oh dear...

Does that mean you won't be using the Sherline CNC options?I think Im going to get the board from gen 6 reprap and 4 steppers, that way I can have a double use cnc and low quality 3d printer.

hectmarr wrote:You have to make many weapons, because this field is long and short life

I think the 3d option will be treated more like a fun sherline accessory that only sees occasional use, while the main goal would be a cheap cnc mill. The way Im designing it the extruder it should be as simple as a sherline headstock to fit then simply plug 3 wires into the main board.

I know its not terribly accurate, but if its strong enough to mill afterwards, you can print oversize and mill important features down, much like a casting.

haha ya, little too expensive for a starving college student. I like the $100 board and $30 for 4 steppers, make my own mounts and couplings alot more than couple hundred maybe 1k for their kits.

I know its not terribly accurate, but if its strong enough to mill afterwards, you can print oversize and mill important features down, much like a casting.

haha ya, little too expensive for a starving college student. I like the $100 board and $30 for 4 steppers, make my own mounts and couplings alot more than couple hundred maybe 1k for their kits.

Patience is a virtue, get it if you can, seldom in a women, never in a man.