No-tool 4" piston valve

Damnit... Oh well, I'll just take it all back in the morning. Tell them I bought all the wrong parts lol. Home depot shouldn't mind to much. A quick question though.. I have to go to a plumbing supply store for Pressure rated, right? and would those fittings cost much more than dwv?

ya, they cost a little more. i didnt know that home depot had 4'' fittings. You dont have to go to a plumbing store, as long as it says "nsf-pw" on it you are ok. Your 3' end cap is fine as it is, but you need to replace the tee and the drain cap with a plug.

- frankrede

- Sergeant Major 2

- Posts: 3220

- Joined: Thu Jul 20, 2006 9:47 pm

- Has thanked: 1 time

- Been thanked: 1 time

Well home depot only has nsf-pw fittings 2" and under usually.

Look in the phone book for Pipe supply stores, Plumbing supply, irrigations supply. or just go to mcmaster.com

Make sure all of your fittings have nsf-pw.

And the fittings usually aren't that much more expensive, well a tleast for me.

Look in the phone book for Pipe supply stores, Plumbing supply, irrigations supply. or just go to mcmaster.com

Make sure all of your fittings have nsf-pw.

And the fittings usually aren't that much more expensive, well a tleast for me.

Current project: Afghanistan deployment

- Blitz

- Corporal 2

- Posts: 627

- Joined: Sat Apr 07, 2007 1:48 am

- Location: Illinois

- Been thanked: 3 times

Pretty much. Around here, all of the major suppliers carry only dwv fittings for anything 2"+, with a few exceptions like couplers and end caps. There's a plumbing/HVAC supplier a few miles from where I am; that's where I get all of my pressure-rated fittings. Which is good, because I gotta start getting my 6" diameter stuff together for my next project.Trey33088 wrote:I just noticed something... Is everything labeled sanitary pretty much DWV?

- schmanman

- Staff Sergeant 2

- Posts: 1685

- Joined: Sat Mar 25, 2006 12:28 pm

- Location: Michigan,U.S.A

- Contact:

awsome!

like they said, dvw.

I have modified my valve, too.

It's not quite as small, but that's because I don know where to get a pressure rated cleanout cap.

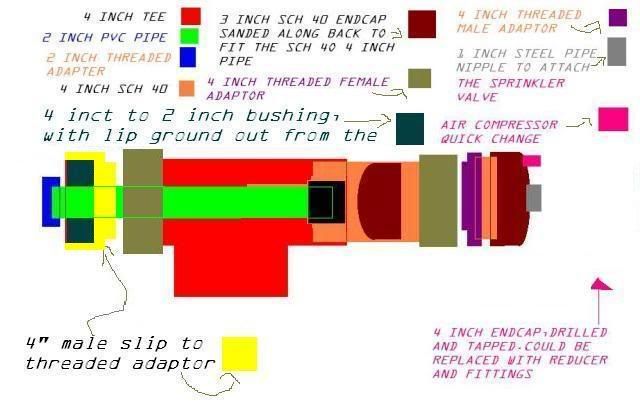

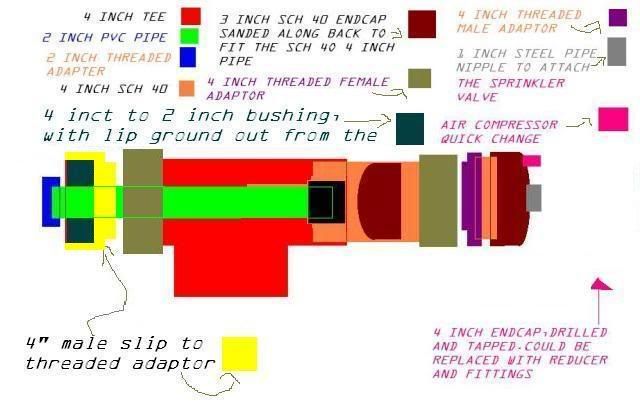

see, here's the updated design.

like they said, dvw.

I have modified my valve, too.

It's not quite as small, but that's because I don know where to get a pressure rated cleanout cap.

see, here's the updated design.

Persistence is a measure of faith in yourself

It looks nice... but if you have not solvent welded it yet, take it apart and return the PVC parts. From my view, the tee, the female adapter, the flush reducing bushing, and the cleanout cap are all unsafe for pressure (NSF-dwv), and I am sure that the cleanout cap will blow after a piston smashes into it.

How is the valve a full 4" port if you made it inside of a 3"x3"x2" tee? It seems to me it could not have a higher port than 2". Even if the valve was made inside of a 4" tee, it would not be able to have full 4" flow (unless you managed to do some maching and used special parts which would technically make it a valve which had 4" of flos; I am not going to get into that now though).

Good attempt and good thinking, but I would try again. I hate to be the jerk who says this, but I would much rather see you in 2 months, out a few dollars but with a nice pressure rated valve that works flawlessly, then right now, with an NSF-dwv valve that doesn't work and will fail if you ever get it to work.

EDIT: Damn, I was REALLY late this this reply

How is the valve a full 4" port if you made it inside of a 3"x3"x2" tee? It seems to me it could not have a higher port than 2". Even if the valve was made inside of a 4" tee, it would not be able to have full 4" flow (unless you managed to do some maching and used special parts which would technically make it a valve which had 4" of flos; I am not going to get into that now though).

Good attempt and good thinking, but I would try again. I hate to be the jerk who says this, but I would much rather see you in 2 months, out a few dollars but with a nice pressure rated valve that works flawlessly, then right now, with an NSF-dwv valve that doesn't work and will fail if you ever get it to work.

EDIT: Damn, I was REALLY late this this reply

Ah I just saw that... its in a 4x4x3 inch T. and yeah, i took it all back lol. realized all of that. i just went and grabbed a few pieces today and crammed together a smaller 2 inch gun with a 1 inch sprinkler valve for now to scratch the itch lol.

Later though, I'll just go back and use all the same part in PW and it should work fine. I'm still debating a few ideas though:

1. Should I drill equalization holes in the piston? or let the air leak around the edge? I was thinking I'd just tap in a 1/4" hole towards the front top edge and install a 1/4" check valve. But ya'll are the experts.

2. If I am supposed to drill holes in the piston, should i grease it before putting it in?

3. Any ideas for a bumper? I'm thing just a nice chunk of garden hose beind the piston, but I'm not so sure. any idea's would be great!

I'll have it built july, though. I'm headed to Basic in the Army july 26, so i wanna have a lil practice lol. (MOS Aircraft Powerplant Repair, Fort Bliss, TX)

Altogether, what i want at the end is this:

Not one, but two 4" valves, both of which are modular and can be used together or separate.

Twin 4" pressure chambers.

A host of barrels, notably a 4" whatever-the-heck-will-fit-in-it barrel, a 2 1/2" tennis ball barrel, a 2" sch80 sleeved 1 1/2"sch21 golf ball barrel, and a 2 maybe 3 inch breechloader.

I want all the parts to be completely modular, just for ease of use and upgrades.

Tell me what you think.

Later though, I'll just go back and use all the same part in PW and it should work fine. I'm still debating a few ideas though:

1. Should I drill equalization holes in the piston? or let the air leak around the edge? I was thinking I'd just tap in a 1/4" hole towards the front top edge and install a 1/4" check valve. But ya'll are the experts.

2. If I am supposed to drill holes in the piston, should i grease it before putting it in?

3. Any ideas for a bumper? I'm thing just a nice chunk of garden hose beind the piston, but I'm not so sure. any idea's would be great!

I'll have it built july, though. I'm headed to Basic in the Army july 26, so i wanna have a lil practice lol. (MOS Aircraft Powerplant Repair, Fort Bliss, TX)

Altogether, what i want at the end is this:

Not one, but two 4" valves, both of which are modular and can be used together or separate.

Twin 4" pressure chambers.

A host of barrels, notably a 4" whatever-the-heck-will-fit-in-it barrel, a 2 1/2" tennis ball barrel, a 2" sch80 sleeved 1 1/2"sch21 golf ball barrel, and a 2 maybe 3 inch breechloader.

I want all the parts to be completely modular, just for ease of use and upgrades.

Tell me what you think.

- BC Pneumatics

- Sergeant

- Posts: 1053

- Joined: Tue Jan 18, 2005 6:55 pm

- Location: Fresno, CA

- Contact:

Erm... What did we say about PW? Don't expect that cleanout to last a terribly long time.

<a href="http://www.bcarms.com/"><img src="http://www.bcarms.com/images/store_logo.png" border="0"> </a>

- Lentamentalisk

- Sergeant 3

- Posts: 1202

- Joined: Tue Aug 07, 2007 5:27 pm

- Location: Berkeley C.A.

why dont you just cut down another rubber donut and glue it to the cleanout cap so that it doesn't get slammed so hard? maybe cut it up some or something like that to make it flex more...

- Pilgrimman

- Specialist 4

- Posts: 480

- Joined: Thu Jun 28, 2007 1:10 pm

- Location: Grants Pass, OR

The last reply was posted months ago.

Anyway, that's an interesting idea, but I don't think you realize how much force a piston will exert when it opens. No amount of rubber will protect it sufficiently, and it's not pressure rated to begin with. USE PRESSURE RATED PARTS.

Anyway, that's an interesting idea, but I don't think you realize how much force a piston will exert when it opens. No amount of rubber will protect it sufficiently, and it's not pressure rated to begin with. USE PRESSURE RATED PARTS.

Yeah, we wouldn't want to anger the bees, now would we??

I HATE YOU BEES! I HATE YOU BEES! I HATE YOU BEES!

LMAO Classic!!!! I love Family Guy!

I HATE YOU BEES! I HATE YOU BEES! I HATE YOU BEES!

LMAO Classic!!!! I love Family Guy!

Hi,

Nice valve, just one thing: Why put a valve for 2" in a 4" casing? it´s about a 1:4 cross section area ratio, or 1:3 when deducting the area taken up by the barrel in the tee. Looks so big to me that I´d say replace the tee by a pipe and call it a coaxial. The chamber is still large enough for that.....

Was 4" chosen to minimize the dynamic pressure loss from chamber to barrel? Or because that was the combination where parts fit best together (the piston in particular)?

I can get ID=50mm end caps that fit inside a 63mm tee after filing away the "lip", and ID=63mm end caps that fit in 75 mm tees... but it seems I am the only one to have seen that kind of stuff...

Regards

Soren

Nice valve, just one thing: Why put a valve for 2" in a 4" casing? it´s about a 1:4 cross section area ratio, or 1:3 when deducting the area taken up by the barrel in the tee. Looks so big to me that I´d say replace the tee by a pipe and call it a coaxial. The chamber is still large enough for that.....

Was 4" chosen to minimize the dynamic pressure loss from chamber to barrel? Or because that was the combination where parts fit best together (the piston in particular)?

I can get ID=50mm end caps that fit inside a 63mm tee after filing away the "lip", and ID=63mm end caps that fit in 75 mm tees... but it seems I am the only one to have seen that kind of stuff...

Regards

Soren