Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

deusXmachina

- Private 4

- Posts: 83

- Joined: Sun Feb 25, 2007 6:06 pm

Sun Apr 29, 2007 7:45 pm

I've kind of run into a dead end with my 3" porting piston cannon because with the current piston, the valve destroys itself on each shot. So we need a much lighter piston. Does anyone have any tips on making lightweight pistons with minimal machining? I'm definitely looking at the two-part bolted piston style like the one on the Supah, but I have no idea where to get the discs. Also, what size all-thread or bolt is sufficient for the center bolt?

Current Piston:

(okay I lied this isn't the exact piston that one is now in pieces but the other one is built more or less the same, i.e. too heavy)

"On a scale from 1-10, I hope you fall in front of a bus."

:white stuff pours out of piston: "What is that? It looks like milk."

"....<i>Well...</i> it's not milk."

YAAAAAAAAYYYY WE'RE DOOMED!

-

Velocity

- Sergeant

- Posts: 1039

- Joined: Tue Feb 07, 2006 5:42 pm

Sun Apr 29, 2007 7:55 pm

What kind of piston is that? For my 3" porting piston valve, I use two endcaps solvent welded together, with an air bumper. I have not had any problems before. My theory is, while a heavy piston certainly is not good for a cannon, a good enough bumper can neutralize these negative effects.

And by the way, if you are using a cleanout cap for the back of the piston valve, replace it; with a valve of this size, it will not be able to survive more than a few shots. Drop $20.50 and get a SCH 80 threaded plug; you will be glad that you did.

-

deusXmachina

- Private 4

- Posts: 83

- Joined: Sun Feb 25, 2007 6:06 pm

Sun Apr 29, 2007 7:58 pm

It's a 3" coupler with a drilled out 3" to 1.5" bushing on one side with a grind plate to keep the sealing surface from buckling. And thanks for the tip on SCH 80 plugs, that will definitely help. We might just have to go with a SCH 80 4" Wye, although a) that's a lot of money and b) it might mess up the geometry. Is the inside of a Sch 80 wye the same diameter as sch 80 PVC pipe? Because the piston extends partway into the wye.

"On a scale from 1-10, I hope you fall in front of a bus."

:white stuff pours out of piston: "What is that? It looks like milk."

"....<i>Well...</i> it's not milk."

YAAAAAAAAYYYY WE'RE DOOMED!

-

Velocity

- Sergeant

- Posts: 1039

- Joined: Tue Feb 07, 2006 5:42 pm

Sun Apr 29, 2007 8:06 pm

Could you possibly provide a close up shot of your valve?

99% of the time, wyes are not pressure rated; they do exist, but they are more like unions (rated low; you can get them on plumbing supply.com, but they are super expensive. $61.87 for a 4" wye, which is only good up to 150 PSI).

I have never seen, nor heard of, a SCH 80 wye.

If I were you, here is what I would do

Buy the following:

(1) 4" SCH 80 plug ($20.50 each)

(2) 4" SCH 40 female adapters ($6.78 each)

(1) 4" Tee ($17.69 each)

(1) 4" Elbow ($11.92)

That comes to a total of $63.67 off of mcmaster.com. Expensive, yes, but how much will it cost to keep replacing those cleanout caps and wyes, time and time again?

-

deusXmachina

- Private 4

- Posts: 83

- Joined: Sun Feb 25, 2007 6:06 pm

Sun Apr 29, 2007 8:14 pm

Is there a drastic difference between the tees you get at Home Depot and a Sch 40 one? I'm actually thinking I might go for a Sch 80 4x3x4 tee (the input is 3"), but I think we will still definitely need a lighter piston.

"On a scale from 1-10, I hope you fall in front of a bus."

:white stuff pours out of piston: "What is that? It looks like milk."

"....<i>Well...</i> it's not milk."

YAAAAAAAAYYYY WE'RE DOOMED!

-

Velocity

- Sergeant

- Posts: 1039

- Joined: Tue Feb 07, 2006 5:42 pm

Sun Apr 29, 2007 9:40 pm

It all depends on what your Home Depot sells...

I wouldn't go for the 4"x4"x3" tee... they are harder to find, and also slightly decrease flow, for the 3" elbow which leads into the tee decreases flow more than a 4" elbow leading into a tee. Besides the 4" tees look much nicer and usually cost less as well.

-

jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Sun Apr 29, 2007 9:45 pm

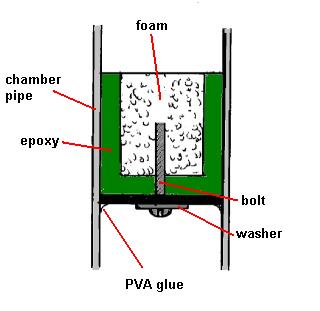

cast it out of quality epoxy... though at that scale, I think it would get pretty expensive.

-

Attachments

-

- cast epoxy pistol construction (vertical)

- piston.JPG (14.38 KiB) Viewed 2300 times

hectmarr wrote:You have to make many weapons, because this field is long and short life