Building or modifying BB, Airsoft, and Pellet type of guns. Show off your custom designs, find tips and other discussion. Target practice only!

-

Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Tue Sep 04, 2007 8:07 pm

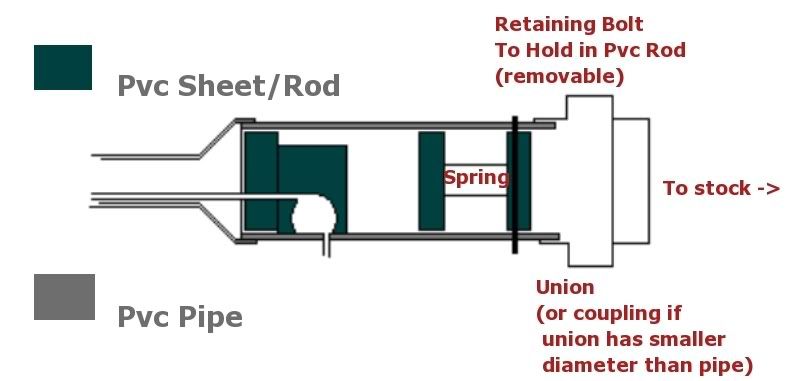

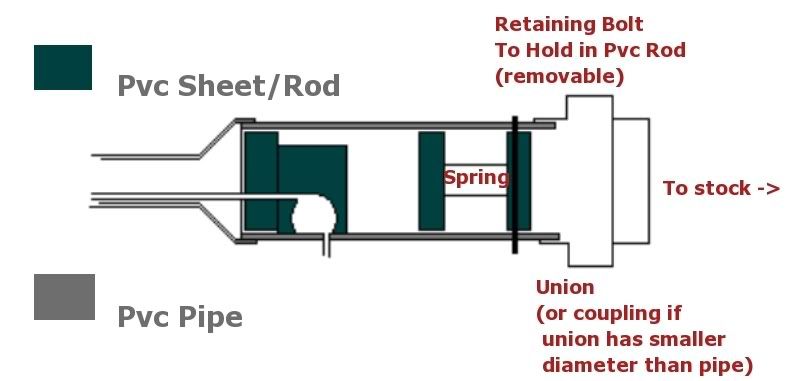

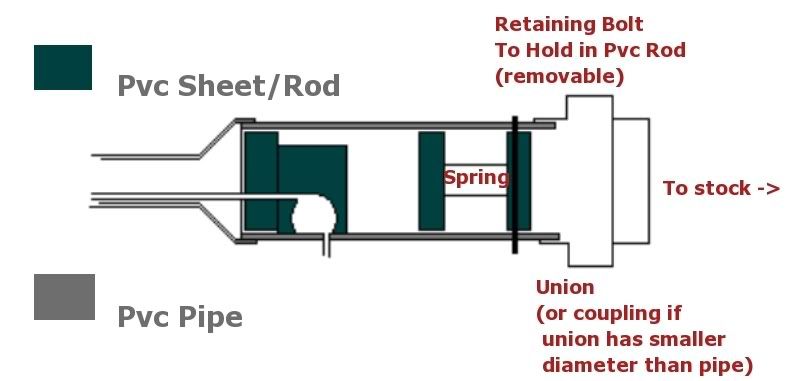

I have wanted to make a good Inline vortex for awhile. Im getting Bored so ive decided to finally try at one. I have some 1.5" pvc rod and 3/4" pvc sheet up on Mcmaster-Carr to use for the vortex block and internal structure. One question first, i want components to be held in by screws that can be removed and re tightened many times. What type of screws should i get?

Design Plans

Last edited by

Panzerfaust on Tue Sep 11, 2007 2:36 pm, edited 4 times in total.

-

Spuddin

- Specialist 2

- Posts: 262

- Joined: Wed May 16, 2007 1:28 pm

- Location: Oklahoma

-

Contact:

Tue Sep 04, 2007 8:31 pm

i would use self tapping screws. be sure to drill a small pilot hole first.

btw i think that u should do alot of measuring first so that your barrel will be in the center of the pipe and vortex block instead at the bottom of the barrel like the diagram shows. the second block i made had a 7/8" hole and it fit just right inside a 2" chamber.

also the retaining bolt is not necessary if the spring is long enough, just let it butt up against the cap. other than that your drawing looks very good.

_______________________

www.freewebs.com/spuddin

-

singularity

- Corporal 5

- Posts: 982

- Joined: Mon Jun 26, 2006 10:53 pm

- Location: someplace

-

Contact:

Tue Sep 04, 2007 8:56 pm

grab a cam lock from Mcmaster-Carr while your at it a lot easier to use than your standard screw off cap or union, makes it easy to reload in the heat of battle. one thing to remember the spring needs to be very weak or the gun will not fire at all in most cases.

-

f.c

- Specialist 3

- Posts: 340

- Joined: Sun Jul 08, 2007 2:40 am

Wed Sep 05, 2007 4:19 am

i don't like how you're barrel is mounted in the pipe. i would center it using some epoxy resin it will increase accuracy alot.

-

Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Wed Sep 05, 2007 5:54 am

Im not to concerned as to if the actual barrel is in the top or bottom of the Barrel shroud pipe, as it will not affect performance at all. The diagram is also of course not to scale, and thats just how the barrel ended up when i drew it. Cams locks are a good idea, i hadent known that Mcmaster-Carr sold them, but i guess they do sell everything. Also, if it helps for any of your dimenshional concerns i am going to be using .177 bb's, 1.5" pipe for main body, and 3/4" pvc sheet for vortex block. I plan to use a 3/4" vortex hole. My spring i just found lying in a droor, i beleive it might be from some old lawn related device. It is not very strong, but incase it is too strong, where can i find Springs for sale?

-

Spuddin

- Specialist 2

- Posts: 262

- Joined: Wed May 16, 2007 1:28 pm

- Location: Oklahoma

-

Contact:

Wed Sep 05, 2007 7:40 am

your local auto parts store should have an assortment of springs or a hardware store maybe.

-

Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Wed Sep 05, 2007 6:03 pm

Would there be any advatage to using 2" pipe instead of 1.5"? 1.5" is convientely like 1.57 ID and thus makes it easy to use 1.5" pvc rod internally.

-

trae08

- Corporal

- Posts: 520

- Joined: Sun Jul 09, 2006 2:14 pm

- Location: florida

Wed Sep 05, 2007 6:41 pm

set screws i think would work best. nice design to

Marvin the Martian: Where's the kaboom? There was supposed to be an earth-shattering kaboom!

Marvin the Martian: The Earth? Oh, the Earth will be gone in just a few seconds.

PCGUY wrote:Congrats, your the first donating member I have had to ban.

-

Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Mon Sep 10, 2007 5:18 pm

NEED HELP *URGENT*

Parts Arrived today, good news and bad news. Good news: pvc rod fits perfectly inside the pipe and can fit through the cam locks. Bad news: Pvc rod CANNOT fit through the male fitting that hooks the cam lock onto the gun. My options as i see them: I am going to use my school's drill press to drill the holes for my vortex block, while i am there i could bore out the inside of the male fitting some using the drill press (the pvc just BARELY dosent fit through) or use the school's drum sander to bore it out if the drill press dosent have the right bit. Other option would be to get either a DWV(know where i can get one) or smaller schedule (maybe sdr21 from tractor supply?) male adapter and hope that the pvc rod will fit through that. I cannot reduce the size of the rod or it will not fit well inside the gun. I could also use any ideas as how to seal the edges of my pvc rod inside the pipe so as to minimize air loss thats not out the barrel.

BTW pvc rod and bar is extremely dense. consider it for future use in projects.

-

noname

- First Sergeant 4

- Posts: 2698

- Joined: Mon Apr 10, 2006 9:19 pm

- Location: Bay Area, CA

Mon Sep 10, 2007 9:47 pm

Why does EVERY SINGLE PERSON who wants to make an inline vortex gun just NEED to have plunger system in it?!?! It just makes the whole thing a lot more complicated, and ends up giving you an assload of problems, and then people just dump the whole project. You DO NOT need a spring and plunger to make an inline vortex gun work! You'll still get at least 80 rounds per second (if you're using a well made vortex block, of course), and the gun takes days less to make, and stil fires great.

3/4" sheet is a bit thick, unless you're using two barrels. It will constrict the flow of BBs around and into the block, decreasing the ROF that you just seem to need so badly.

-

Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Tue Sep 11, 2007 5:58 am

???

Even without a plunger system i still need the rod sealed for other parts. If you feel 3/4 sheet is too wide for 1.5" pipe what do you think would be better? I might be able to make a skinnier piece with the school's equipment. Remember i am using .177 bb's. I also am building a vortex gun witht the express purpose of not having to be pointing it down to shoot. I want a plunger, and besides my unfortunate fitting it shouldent really be that hard to make.

After having some time to look over things and how they fit, your definetely right, 3/4 sheet is too thick to be used in 1.5" pipe. In fact i am questioning my use of 1.5" entirely, and thinking of returning my parts and re-ordering everything scaled to 2" size. Did you not recomend 3/4 just because i was using 1.5" pipe or because 3/4 is too thick in general? If so i could get 1/2" instaed.

-

Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Tue Sep 11, 2007 4:50 pm

Um Guys im about to return this stuff to McMaster and re-order in 2" sizes and 1/2" cortex sheet instead of 3/4"... Could i maybe get some confirmation from people that have built one of these so i am sure that .5" wide vortex block in 2" pipe is good...

-

singularity

- Corporal 5

- Posts: 982

- Joined: Mon Jun 26, 2006 10:53 pm

- Location: someplace

-

Contact:

Tue Sep 11, 2007 5:41 pm

I also am building a vortex gun witht the express purpose of not having to be pointing it down to shoot.

i have built an airsoft vortex with no plunger, it has been battle tested on many occasions. i have never had it fail to fire because of some odd angle and in most cases the gun isn't pointed more than 15 degrees up, with a full hopper it isn't a problem.

-

Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Tue Sep 11, 2007 6:43 pm

Singularity, i realise that a plunger system is not neccesary, but i already have to order the pvd rod for other things, at even if the chance of performance boost is tiny i migh as well try. Right now my most nagging question is what width to make the vortex block, upon observation 3/4" was far to wide for 1.5" pipe. However, now that i plan to use 2" pipe, would there be an advatage in 3/4? or should i use 1/2? Seems to me like the wider block would get more bb's trapped in the vortex at once, increasing ROF.