Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

NatoHub

- Private 2

- Posts: 31

- Joined: Mon May 14, 2007 3:48 pm

Mon Nov 12, 2007 5:53 pm

Sorry if this is in the wrong spot (I already had a look at the spud Wiki btw).

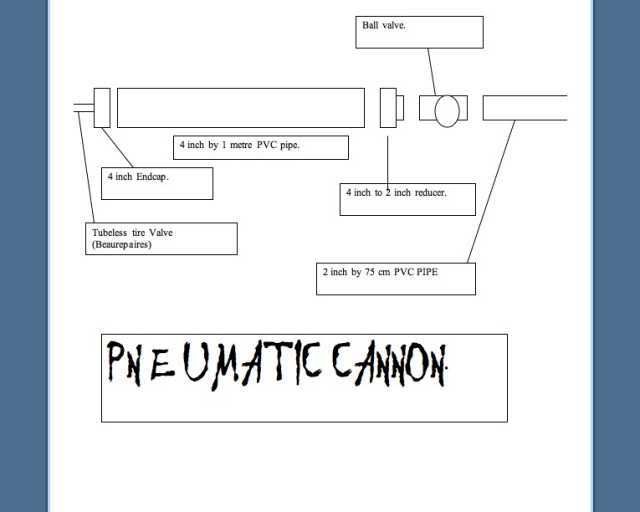

I already have a 2" Combustion cannon. I'm a Pneumatic "Pneub" but would like to make one. If I pretty much followed these plans, will I have good results?

Also, how easy is it to use a sprinkler valve vs a ball valve (obviously a sprinkler v. gives better results but how hard is it to modify).

Basically I just want to make a decent beginner cannon that is simple and as cheap as possible.

Thanks!

-

mopherman

- Corporal 3

- Posts: 788

- Joined: Sat Feb 03, 2007 8:20 pm

- Been thanked: 1 time

Mon Nov 12, 2007 5:59 pm

your diagram looks great so far. the only problem is the 4-2 reducer. you need to use a coupler and reduce bushing. modding a sprinkler valve is easy. just drill a hole in the top and tap a 1/4 nipple in.

searching for a modern day savior from another place,inclined toward charity,everyone's begging for an answer,without regard to validity,the searching never ends,it goes on and on for eternity

-Bad religion

-

hi

- Staff Sergeant 2

- Posts: 1619

- Joined: Thu Feb 01, 2007 9:28 pm

Mon Nov 12, 2007 5:59 pm

the cannon will work. i suggest a bushing rather than a bell reducer because they are stronger.

modding a sprinkler valve is very very easy. you literally just drill a hole and screw in a blow gun. there are not tricks or thrills, its that simple. just be sure to plug any holes with epoxy.

make sure everytime is pressure rated...

"physics, gravity, and law enforcement are the only things that prevent me from operating at my full potential" - not sure, but i like the quote

you know you are not an engineer if you have to remind yourself "left loosy righty tighty"

-

NatoHub

- Private 2

- Posts: 31

- Joined: Mon May 14, 2007 3:48 pm

Mon Nov 12, 2007 6:03 pm

your diagram looks great so far

ha...I actually just found that image in the Album on this site

Could anyone link me to instructions on modifying a sprinkler valve?

So far I thing it would go:

Schrader Valve > Encap > Chamber > Some sort of reducer > Sprinkler Valve > Barrel

Sound about right?

Thanks everyone

-

mopherman

- Corporal 3

- Posts: 788

- Joined: Sat Feb 03, 2007 8:20 pm

- Been thanked: 1 time

Mon Nov 12, 2007 6:08 pm

yup. basic pneumatics are a no-brainer. just make sure you use pressure rated parts and primer/cement .

searching for a modern day savior from another place,inclined toward charity,everyone's begging for an answer,without regard to validity,the searching never ends,it goes on and on for eternity

-Bad religion

-

the beast

- Private 2

- Posts: 22

- Joined: Wed Sep 12, 2007 9:00 pm

Mon Nov 12, 2007 6:22 pm

For a pneumatic a .6-.8 to 1 is a perfect ratio but 1:1 is also good. With a hand pump it just depends how much pressure your pump holds and how tired you want to get. Most basic bike pumps will hold 90Psi reasonably. Youd get pretty good power especially with that huge chamber!

-

DYI

- First Sergeant 5

- Posts: 2862

- Joined: Sat Jul 07, 2007 8:18 pm

- Location: Here and there

Mon Nov 12, 2007 7:07 pm

If you plan on using standard compressor pressures, .2:1 is a good ratio to aim for if you have a fixed chamber size. Very efficient, and you can therefore get as much power as possible out of a given chamber size.

You really should download GGDT so that you don't have to ask us these questions.

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

-

Hubb

- First Sergeant 2

- Posts: 2390

- Joined: Mon May 28, 2007 8:39 am

- Location: South Georgia

-

Contact:

Mon Nov 12, 2007 7:10 pm

DYI wrote:...You really should download GGDT so that you don't have to ask us these questions.

Not trying to steal the thread, but has GGDT got back online yet from the site? I haven't checked but a while back, it was not available. If not, I have uploaded it with RapidShare and can give a copy if needed.

-

NatoHub

- Private 2

- Posts: 31

- Joined: Mon May 14, 2007 3:48 pm

Mon Nov 12, 2007 7:11 pm

2:1 ratio...meaning that if I had a 4" wide chamber and a 2" wide barrel, the barrel would have to be a quarter as long as the chamber?

-

DYI

- First Sergeant 5

- Posts: 2862

- Joined: Sat Jul 07, 2007 8:18 pm

- Location: Here and there

Mon Nov 12, 2007 7:34 pm

A given length of 4" pipe has 4 times the volume as the same length of 2" pipe. For a 2:1 ratio you would need a barrel twice the length of the chamber. For a .2:1 ratio, you would need a pipe 20x the length of the chamber.

And I didn't write 2:1 ratio, I wrote .2:1 (as in 0.2:1)

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

-

jimmy101

- Sergeant Major 2

- Posts: 3210

- Joined: Wed Mar 28, 2007 9:48 am

- Location: Greenwood, Indiana

- Has thanked: 6 times

- Been thanked: 18 times

-

Contact:

Tue Nov 13, 2007 12:11 pm

Like others have said, definitely go with the sprinkler valve instead of the ball valve.

You don't have to mod the sprinkler valve right away. Fire the gun a few times with the solenoid. When you get the time and parts you can add the blowgun trigger later.

You might as well leave the solenoid trigger valve in place. It really doesn't affect the gun's performance and you can still use it if you move the valve to another gun.

That is one of the nice things about sprinkler valves, they are usually threaded parts so they can be swapped from gun to gun. Most ball valves are solvent welded in place so it is not usually practical to move the valve from gun to gun.