The propane tank would actually get replaced with a separate chamber that propane or co2 can get injected into.

It works in the same way that THISworks.

My design would incorporate a metal hopup chamber and would use Airsoft Magazines. There might also be a flow control valve between the tank and the pressure washer handle.

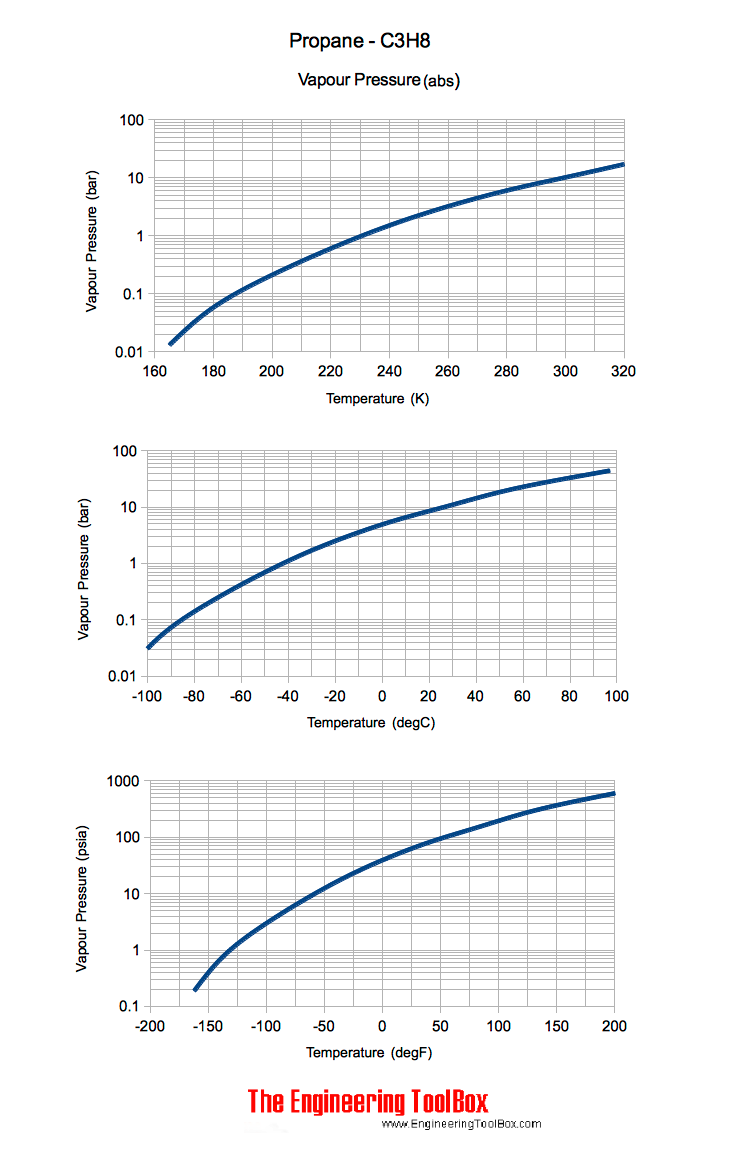

The popoff that I would use would operate at a lower psi so I can use propane without any problems (100psi popoff.)

What do you guys think?