Northir wrote:im trying to build this with my fridge i cut the pipes off at the fitting of the compressor, since mine has little barbs that i can attach a 3/8" hose to, anyways, instead of 2 hoses this one has 4 outputs, 2 went into a heatsinc looking thing, i cut it off, and one went into the back heat sync and another into the top back of the fridge, when i cut that one it had a wire inside, i plug it in and it hums but i dont have any air flow, thoughts?

You may find the pipe with the "Wire inside" is the expansion valve. In a refrigerator this is often a small tube between the condensor and evaporator. It meters high pressure liquid freon to the low pressure evaporator in the icebox where it boils and takes away heat.

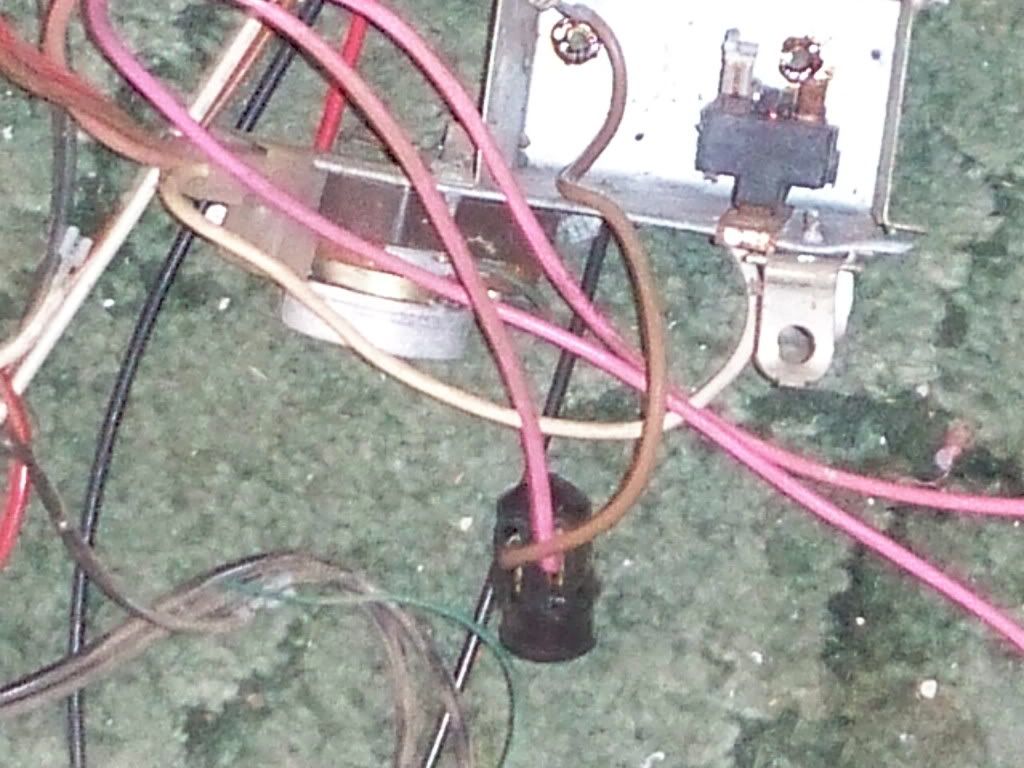

The high pressure output from the compressor goes to the "heatsink" condensor coil on the back of the fridgerator. The tube leading from the evaporator is the low side tube that goes to the inlet of the compressor. Without a photo, I'm not sure where or what the other two tubes are. Some compressors have a crankcase loop to heat the crankcase to boil out freon that dissolves into oil to prevent it from foaming up when the compressor starts.

A photo showing all 4 tubes would be helpful. Many compressors have 3 tubes. An inlet, outlet and a process tube. The process tube is the tube used in manufacture to pump out the system and charge it with freon. The process tube is most often sealed shut after manufacture.