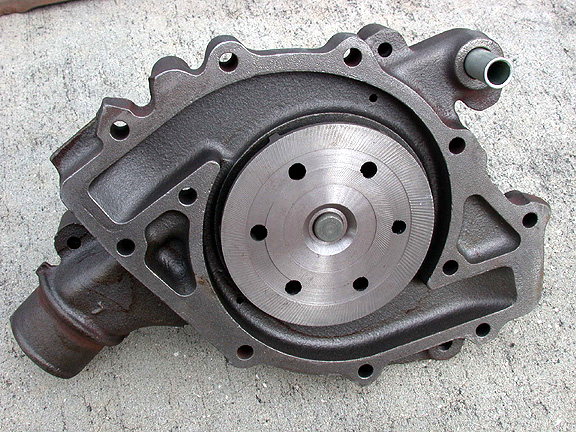

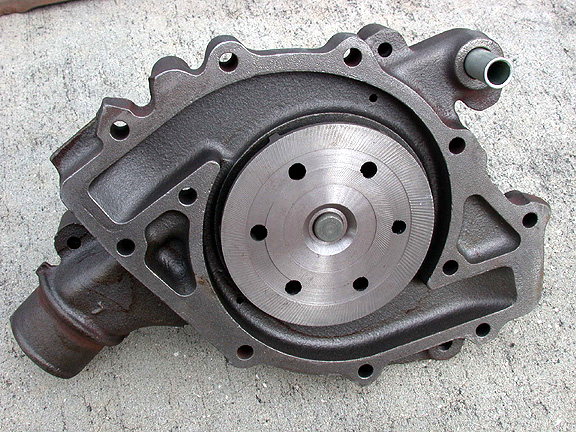

ever consider a water pump? with some reverse engineering... This might work for you. They are dirtttt cheap too.

ever consider a water pump? with some reverse engineering... This might work for you. They are dirtttt cheap too.High pressure (liquid) pumps

- MadPiper2.0

- Private 2

- Posts: 34

- Joined: Sat Oct 16, 2010 4:05 pm

ever consider a water pump? with some reverse engineering... This might work for you. They are dirtttt cheap too.

ever consider a water pump? with some reverse engineering... This might work for you. They are dirtttt cheap too.- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

That kind of pressure and above is normal in hydraulic systems. That kind of pressure in an air fuel mix is not recommended. Google search it. Oil under pressure does not ignite without an oxidizer present.MadPiper2.0 wrote: I really wouldn't recommend putting that kind of pressure on a petroleum based fuel. It's likely that the compression could cause spontaneous combustion. Sometimes in gasoline engines if the spark plug doesn't fire, the compression cycle alone can cause detonation.

Hydraulic pumps supply fluid to the components in the system. Pressure in the system develops in reaction to the load. Hence, a pump rated for 5000 psi is....

Have you seen his pressure and volume requirement?ever consider a water pump?

- MadPiper2.0

- Private 2

- Posts: 34

- Joined: Sat Oct 16, 2010 4:05 pm

I don't need to google search it, I am an ASE certified Master tech. I never said that it WILL ignite, I am saying putting a petroleum based fuel under a lot of pressure is dangerous. Would gun powder ignite if you hit it with a hammer? Probably not, but is it safe? No.Technician1002 wrote:That kind of pressure and above is normal in hydraulic systems. That kind of pressure in an air fuel mix is not recommended. Google search it. Oil under pressure does not ignite without an oxidizer present.MadPiper2.0 wrote: I really wouldn't recommend putting that kind of pressure on a petroleum based fuel. It's likely that the compression could cause spontaneous combustion. Sometimes in gasoline engines if the spark plug doesn't fire, the compression cycle alone can cause detonation.

Hydraulic pumps supply fluid to the components in the system. Pressure in the system develops in reaction to the load. Hence, a pump rated for 5000 psi is....Have you seen his pressure and volume requirement?ever consider a water pump?

Yes! I have seen his pressure requirements and I am suggesting a safer alternative if your small mind can't wrap around it. He still hasn't really even said what exactly he is trying to do so I feel my contributions are a lot more valid than your input.

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

I did see that he posted his design requirements in the first post. He did not need to post what it was for if the pump specs are listed. What centrifugal pump did you have in mind to meet the requirements? I don't know of any high pressure low volume pumps in that category.pump that would be able to pressurize liquids to 700-1000 PSI. Flow rates are minimal, only about 300 cc/min

Please review the rules.. Button is at the top of the page.. Start with #1.if your small mind can't wrap around it.

- Gippeto

- First Sergeant 3

- Posts: 2504

- Joined: Sat Jan 19, 2008 10:14 am

- Location: Soon to be socialist shit hole.

- Has thanked: 2 times

- Been thanked: 17 times

Direct injection anyone?  Believe he mentioned it too.

Believe he mentioned it too.

Certain requirements are implied by "Direct injection" are they not? (Hint...think "Rudolph Diesel".)

The 100psi or so you MIGHT get from a centrifical pump wouldn't cut it with typical cylinder cranking pressures...now would it master tech?

Certain requirements are implied by "Direct injection" are they not? (Hint...think "Rudolph Diesel".)

The 100psi or so you MIGHT get from a centrifical pump wouldn't cut it with typical cylinder cranking pressures...now would it master tech?

"It could be that the purpose of your life is to serve as a warning to others" – unknown

Liberalism is a mental disorder, reality is it's cure.

Liberalism is a mental disorder, reality is it's cure.

- MadPiper2.0

- Private 2

- Posts: 34

- Joined: Sat Oct 16, 2010 4:05 pm

Yes he did say direct injection. I was hoping for something more specific, when it comes to this kind of thing specifics can make a VERY big difference. He also said it was for a "science fair project" so you would imagine it has to be demonstrated. I don't think building it in full scale is either necessary or safe for a science fair project.Gippeto wrote:Direct injection anyone?Believe he mentioned it too.

Certain requirements are implied by "Direct injection" are they not? (Hint...think "Rudolph Diesel".)

The 100psi or so you MIGHT get from a centrifical pump wouldn't cut it with typical cylinder cranking pressures...now would it master tech?

P.S. There is negative pressure in an engine during the intake stroke. You don't get any pressure until the "compression" stroke which happens AFTER the intake stroke. The intake stroke is when the air and fuel enters the cylinder. Don't believe me? Pop out a spark plug and do a compression test!! High flow is more important than high pressure.

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

Just an FYI, Centrifugal pumps are used for high pressure applications. A common use is in electric deep well water pumps. The cascaded stages often exceed 5 series stages. They are not low volume pumps however and will overheat with low flow.

Direct injection indeed. While high pressure petrol is not a necessity, it'd be nice. High pressure water (injected near the top of the exhaust stroke with both valves closed) is necessary. Not the 29,000 PSI of diesel (yes, they 'compress' hydrocarbons that hard. And those hydrocarbons are much more prone to dieseling than gasoline.MadPiper2.0 wrote:

P.S. There is negative pressure in an engine during the intake stroke. You don't get any pressure until the "compression" stroke which happens AFTER the intake stroke. The intake stroke is when the air and fuel enters the cylinder. Don't believe me? Pop out a spark plug and do a compression test!! High flow is more important than high pressure.

One of the main advantages of having a high pressure fuel system is the tendency for the turbulence to atomize the spray. Also, I could inject fuel at some time with positive cylinder pressure.

I highly advise that you not badmouth Tech; he knows his stuff.

With regard to "moar flow = better" (paraphrased), just no. I don't want to run rich, flood the engine, grossly contaminate the oil, or burn up tons of power pumping pack into a reservoir. The 300cc/min includes a hefty safety margin.

POLAND_SPUD wrote:even if there was no link I'd know it's a bot because of female name

- Gippeto

- First Sergeant 3

- Posts: 2504

- Joined: Sat Jan 19, 2008 10:14 am

- Location: Soon to be socialist shit hole.

- Has thanked: 2 times

- Been thanked: 17 times

@ piper...

Done more than one compression test...

Diesels inject the fuel while the cylinder is undergoing the compression stroke...I'll feely admit I made an assumption that it would work the same way with direct injection of gasoline....

If I'm in error...well then that's my bad.

After a few minutes research, it seems that the fuel is/can be injected during both the intake and compression strokes. Fuel rail pressures are ~ 2200psi to allow sufficient volume to be injected in the alloted time.

Sounds like a cool project. 8)

Done more than one compression test...

Diesels inject the fuel while the cylinder is undergoing the compression stroke...I'll feely admit I made an assumption that it would work the same way with direct injection of gasoline....

If I'm in error...well then that's my bad.

After a few minutes research, it seems that the fuel is/can be injected during both the intake and compression strokes. Fuel rail pressures are ~ 2200psi to allow sufficient volume to be injected in the alloted time.

Sounds like a cool project. 8)

"It could be that the purpose of your life is to serve as a warning to others" – unknown

Liberalism is a mental disorder, reality is it's cure.

Liberalism is a mental disorder, reality is it's cure.

Oh, Gippeto

Do you know if the electric pressure washers use an unloader valve like a gasoline one, or do they just turn off/down the motor?

Thanks!

Do you know if the electric pressure washers use an unloader valve like a gasoline one, or do they just turn off/down the motor?

Thanks!

POLAND_SPUD wrote:even if there was no link I'd know it's a bot because of female name

- Gippeto

- First Sergeant 3

- Posts: 2504

- Joined: Sat Jan 19, 2008 10:14 am

- Location: Soon to be socialist shit hole.

- Has thanked: 2 times

- Been thanked: 17 times

They have an unloader.

"It could be that the purpose of your life is to serve as a warning to others" – unknown

Liberalism is a mental disorder, reality is it's cure.

Liberalism is a mental disorder, reality is it's cure.

thanks!

What does anyone think about putting an accumulator upstream of the unloader? The unloader will end up being at least the first stage of the fuel pressure regulator. Ideally the only stage, since I'm lazy.

Anyone input on keeping this cool, since it will be putting out so little flow? Gasoline cavitates easier than water, so I really need to keep temps down. I assume I'll end up running what the accumulator relieves back into the gas tank.

Do I need a regular pump of some kind to feed the pressure washer, or will it "suck" sufficiently? For use at high flows, etc. I know your water supply flow rate must be able to exceed the flow rate of the power washer.

What does anyone think about putting an accumulator upstream of the unloader? The unloader will end up being at least the first stage of the fuel pressure regulator. Ideally the only stage, since I'm lazy.

Anyone input on keeping this cool, since it will be putting out so little flow? Gasoline cavitates easier than water, so I really need to keep temps down. I assume I'll end up running what the accumulator relieves back into the gas tank.

Do I need a regular pump of some kind to feed the pressure washer, or will it "suck" sufficiently? For use at high flows, etc. I know your water supply flow rate must be able to exceed the flow rate of the power washer.

POLAND_SPUD wrote:even if there was no link I'd know it's a bot because of female name

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

If you use an accumulator, you will want to use a check valve and place it downstream of the unloader. The unloader on many pressure washers open on pressure and remain open on flow, so while unloaded, the output pressure is relatively low. This is listed as a Flow Sensitive Unloader. This is why the gas engines load and throttle up when there is flow demand and the unloader closes the bypass instead of holding the pressure high. Reducing the power input when idle reduces the generation of heat and wear.

Since a pressure washer is a positive displacement pump, using a pressure sensor and a DC motor or variable speed AC motor, you can have it maintain pressure in an accumulator much like an airless paint gun.

Since a pressure washer is a positive displacement pump, using a pressure sensor and a DC motor or variable speed AC motor, you can have it maintain pressure in an accumulator much like an airless paint gun.

Gotcha. I was under the impression that a flow sensitive unloader was a luxury. Is it likely the unloader will cycle constantly? is it harmful?

I read that they are bad at pulsing loads, so I will likely have my regulator relieve excess pressure, rather than just close.

I take it I will need a separate fuel pressure regulator.

Do you suppose an uncontrolled induction motor would reduce current consumption while unloaded (since less torque would be required, since pressure would be low)? I REALLY don't want to make an inverter.

I read that they are bad at pulsing loads, so I will likely have my regulator relieve excess pressure, rather than just close.

I take it I will need a separate fuel pressure regulator.

Do you suppose an uncontrolled induction motor would reduce current consumption while unloaded (since less torque would be required, since pressure would be low)? I REALLY don't want to make an inverter.

POLAND_SPUD wrote:even if there was no link I'd know it's a bot because of female name

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

An induction motor does draw less power when not under a load. Often the current remains relatively high depending on the power factor of the motor. Some motors when running low power run with high reactive current. Often capacitors are used to cancel the reactive current to reduce the current draw.

Here is more info in the subject if you study the electrical end of induction motors. Avoid the link if you don't have an electrical background. It won't make sense if you don't understand phase angle and power factor.

http://www.usmotors.com/products/ProFacts/1-115.htm

More info on various configurations of induction motors is here;

http://www.allaboutcircuits.com/vol_2/chpt_13/9.html

Here is more info in the subject if you study the electrical end of induction motors. Avoid the link if you don't have an electrical background. It won't make sense if you don't understand phase angle and power factor.

http://www.usmotors.com/products/ProFacts/1-115.htm

More info on various configurations of induction motors is here;

http://www.allaboutcircuits.com/vol_2/chpt_13/9.html