qev proplems ! ANSWER FOUND

- bravootome

- Specialist 3

- Posts: 334

- Joined: Mon Oct 14, 2013 11:11 am

- Has thanked: 1 time

- Been thanked: 2 times

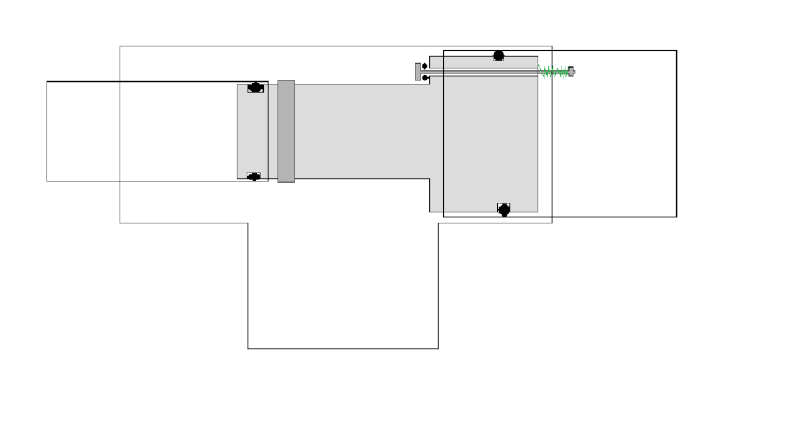

i am working on another qev fully machined so i avoid all those problems i had before, i mean a perfect piston in a perfect body. it is a multishoot.

this time the problem is that when i press to shoot that bang is not there, is only a fsssss, the bang comes at higher pressures over 10 bar( but still not that clear bang ). this fssss makes the gun very low power and performance. slower i press the pilot, bigger the fssss is. i made the piston area pretty large for the 6 mm gun, in order to decompress really easy. on previos tests i just had to touch a little the pilot's trigger and the piston responded prompt---- bang !

if you had this problem how you fixed it ? i use as a pilot the pilot from another working gun........

ANSWER : all those troubles comes from the wrong idea that bigger the diameter of the piston, faster and easier it would open, well not. Is a matter of physics. smaller it is, faster and easier it opens(since it press against 6mm pipe with lowerr power), with only few air piloted. So today i made a 10.5 mm piston(and housing) ( the previous piston had 21 mm.)for a sealing surface of 7-8 mm and i was right, now, it opens extremely easy and fast, but i will have to decreases pilot's volume( or to remake the piston larger, like 12-13 mm). but also the problem is that it pretty hard for this piston to seal the surface, no matter what i tried( only a hard spring does it).

i forgot to mention that the piston must open few mm by restricting him to travel more.

this time the problem is that when i press to shoot that bang is not there, is only a fsssss, the bang comes at higher pressures over 10 bar( but still not that clear bang ). this fssss makes the gun very low power and performance. slower i press the pilot, bigger the fssss is. i made the piston area pretty large for the 6 mm gun, in order to decompress really easy. on previos tests i just had to touch a little the pilot's trigger and the piston responded prompt---- bang !

if you had this problem how you fixed it ? i use as a pilot the pilot from another working gun........

ANSWER : all those troubles comes from the wrong idea that bigger the diameter of the piston, faster and easier it would open, well not. Is a matter of physics. smaller it is, faster and easier it opens(since it press against 6mm pipe with lowerr power), with only few air piloted. So today i made a 10.5 mm piston(and housing) ( the previous piston had 21 mm.)for a sealing surface of 7-8 mm and i was right, now, it opens extremely easy and fast, but i will have to decreases pilot's volume( or to remake the piston larger, like 12-13 mm). but also the problem is that it pretty hard for this piston to seal the surface, no matter what i tried( only a hard spring does it).

i forgot to mention that the piston must open few mm by restricting him to travel more.

Last edited by bravootome on Mon Nov 25, 2013 1:16 pm, edited 7 times in total.

come undone

- wyz2285

- First Sergeant 2

- Posts: 2388

- Joined: Sat Mar 06, 2010 7:50 am

- Location: Porto, Portugal

- Has thanked: 1 time

- Been thanked: 4 times

- Contact:

photos? I'm not sure if your piston is too tight (so only high pressure moves the piston).

Obviously slower you open the pilot, slower the piston opening (on a non-airtight piston)

Obviously slower you open the pilot, slower the piston opening (on a non-airtight piston)

CpTn_lAw wrote:"yay, me wanna make big multishot pnoob with 1000 psi foot pump compressor using diamond as main material. Do you think wet bread make good sealant? "

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

hectmarr wrote:You have to make many weapons, because this field is long and short life

- bravootome

- Specialist 3

- Posts: 334

- Joined: Mon Oct 14, 2013 11:11 am

- Has thanked: 1 time

- Been thanked: 2 times

wyz2285 wrote:photos? I'm not sure if your piston is too tight (so only high pressure moves the piston).

Obviously slower you open the pilot, slower the piston opening (on a non-airtight piston)

no, it not tight. at my other gun, doesnt matter how fast i push the pilot, it works the same,a good bang.

i notice the too much air is loosed from pilot just for a small decompresion of the piston. if i correct the semiauto spring like it should be( softer) the piston doesn't open at all. i tried i tighter/smaller piston but i got same thing.

instead of 30 shoots per one fill i got 15 very low power shoots.

Last edited by bravootome on Fri Nov 15, 2013 2:00 pm, edited 1 time in total.

come undone

- bravootome

- Specialist 3

- Posts: 334

- Joined: Mon Oct 14, 2013 11:11 am

- Has thanked: 1 time

- Been thanked: 2 times

i got same thing back here but without o-rings. machined.

come undone

- bravootome

- Specialist 3

- Posts: 334

- Joined: Mon Oct 14, 2013 11:11 am

- Has thanked: 1 time

- Been thanked: 2 times

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

How is the piston sealing face attached?

Also, you don't need the spring.

Also, you don't need the spring.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- bravootome

- Specialist 3

- Posts: 334

- Joined: Mon Oct 14, 2013 11:11 am

- Has thanked: 1 time

- Been thanked: 2 times

I USED SUPERGLUE, the spring is needed when you inflate with air, or the piston is pushed back an air exits the barrel.jackssmirkingrevenge wrote:How is the piston sealing face attached?

Also, you don't need the spring.

bravootome wrote:if i use o-ring i wouldn't get semiauto with what i have already made.dart guy wrote:soka, a floated and noched o ring would be just as good

and what for is the check valve for? i suspect when piston gets back the valve allow semiauto. but you wont get equal fires on different pressure this way ! cuz it allows semiauto only when the piston has travelled a distance back. different pressures = different piston speeds and distance to move.

Last edited by jrrdw on Fri Nov 15, 2013 8:11 am, edited 2 times in total.

Reason: Double posting. Triple posting!

Reason: Double posting. Triple posting!

come undone

- bravootome

- Specialist 3

- Posts: 334

- Joined: Mon Oct 14, 2013 11:11 am

- Has thanked: 1 time

- Been thanked: 2 times

i meant, that will work perfect.When you whrited a perfect QEV i see that design!

Last edited by jrrdw on Fri Nov 15, 2013 3:18 pm, edited 1 time in total.

Reason: Fixed tag.

Reason: Fixed tag.

come undone

I’m not quite sure with your multi shoots gun design but I assume since it need a spring behind its piston, it is a chamber filled or at least all the air for the second and next shoot is kept in the chamber and not the pilot filled that usualy use two way or sliding valve for piloting (if this is a wrong assumption you can just ignore my post). All my guns are in this design (except mine are pvc and use lower pressure). Based on my experience, when I got fssss, most cases were caused by my pilot valve. The pilot valve is not big or quick enough to decompress the pilot area. I solve the problem by making the valve bigger or the hammer stronger (I use hammer valve for piloting). I know that you use a pilot valve from other gun that is working but is it the gun with the same piston size or pilot area or spring strength?

The other causes are that the piston is to lose and let too many air flowing from the chamber to the pilot area or/and the spring is to strong. However, for these causes I have my own consideration, that when the piston is too tight or/and the spring is too weak, it let the piston open too long (and sometime just keep open until all the air in the chamber gone) so I chose to have too lose piston and to strong spring then the opposite.

I do have some question for you. What do you use for piloting the valve? Is it pop up valve that pressed manually? If so how you control the consistency of each shoot, since it should be different for long or short press. And the last one, for multi shoots with 6 mm barrel, why you choose piston valve rather than just a hammer valve?

The other causes are that the piston is to lose and let too many air flowing from the chamber to the pilot area or/and the spring is to strong. However, for these causes I have my own consideration, that when the piston is too tight or/and the spring is too weak, it let the piston open too long (and sometime just keep open until all the air in the chamber gone) so I chose to have too lose piston and to strong spring then the opposite.

I do have some question for you. What do you use for piloting the valve? Is it pop up valve that pressed manually? If so how you control the consistency of each shoot, since it should be different for long or short press. And the last one, for multi shoots with 6 mm barrel, why you choose piston valve rather than just a hammer valve?

honey,.. for my next birthday, a lot of epoxy will be enough as the present

- bravootome

- Specialist 3

- Posts: 334

- Joined: Mon Oct 14, 2013 11:11 am

- Has thanked: 1 time

- Been thanked: 2 times

AS a pilot, i made a sort of a push of a buton valve, i control the consistency but not for eachshoot,, cuz it self regulated by a 3rd valve that makes this auto regulation. i control only the power of shoots by a spring inside the 3rd valve. there is a diagram of my pilot in my previos post.

i choose qev cuz i is a lot more powerfull( i also got a 6 mm hammervalve) and most of the shoots have same consistency and you dont have to load a hammer for each shoot, you just fire. i also made 2 years ago a 8 mm multishoot qev that works perfectly even today after at least 20-30.000 shoots. But damn if i know how i made it that good. i made this 6 mm one with almost same parts.

i choose qev cuz i is a lot more powerfull( i also got a 6 mm hammervalve) and most of the shoots have same consistency and you dont have to load a hammer for each shoot, you just fire. i also made 2 years ago a 8 mm multishoot qev that works perfectly even today after at least 20-30.000 shoots. But damn if i know how i made it that good. i made this 6 mm one with almost same parts.

Last edited by bravootome on Sun Nov 17, 2013 12:10 pm, edited 1 time in total.

come undone

- bravootome

- Specialist 3

- Posts: 334

- Joined: Mon Oct 14, 2013 11:11 am

- Has thanked: 1 time

- Been thanked: 2 times

how do you see the piston diameter in relation with the sealing surface diameter in order to a good decompresion.

Last edited by bravootome on Sun Nov 17, 2013 12:12 pm, edited 1 time in total.

come undone