Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

Wed Mar 28, 2007 6:23 pm

well Its going to be a while befor I make a gun with this design I kinda feel guilty for not sharing this since its one of my better ideas

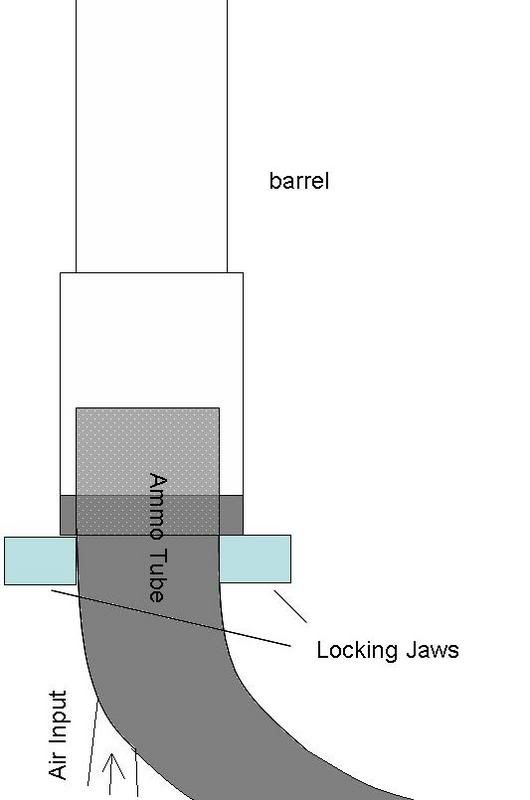

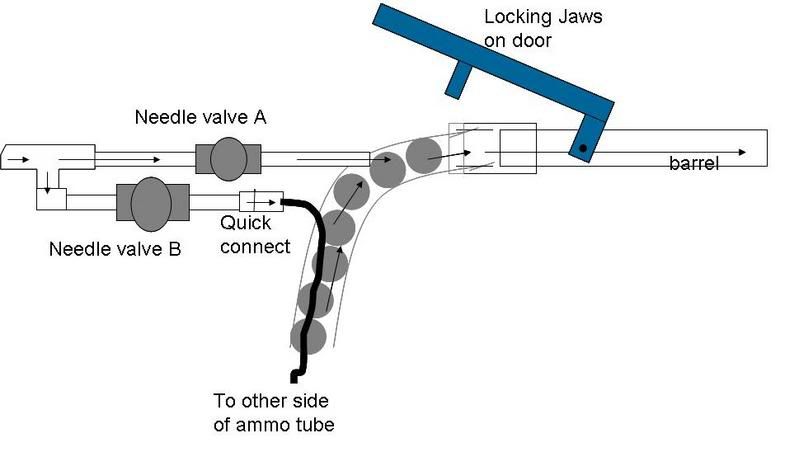

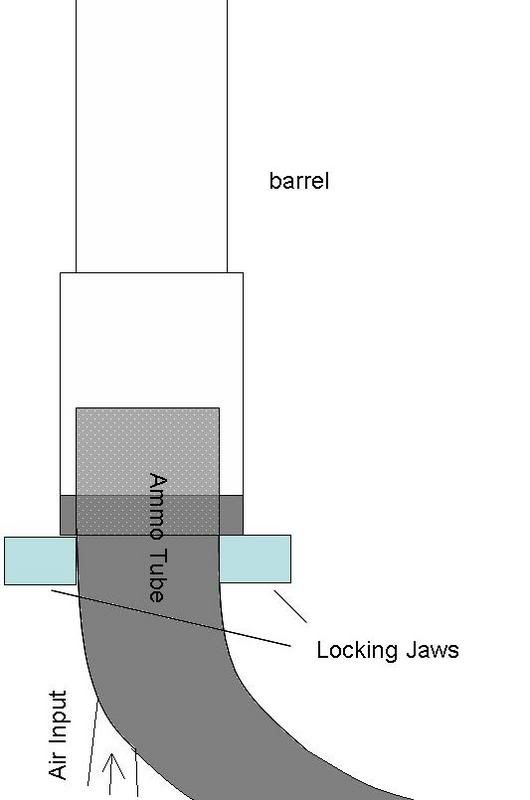

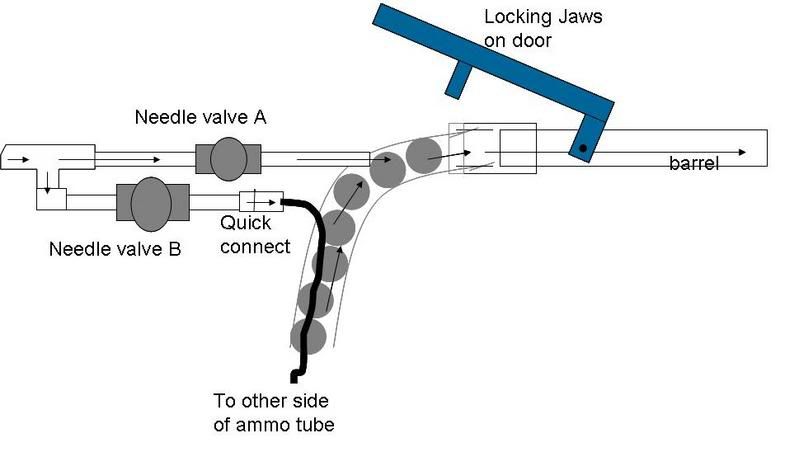

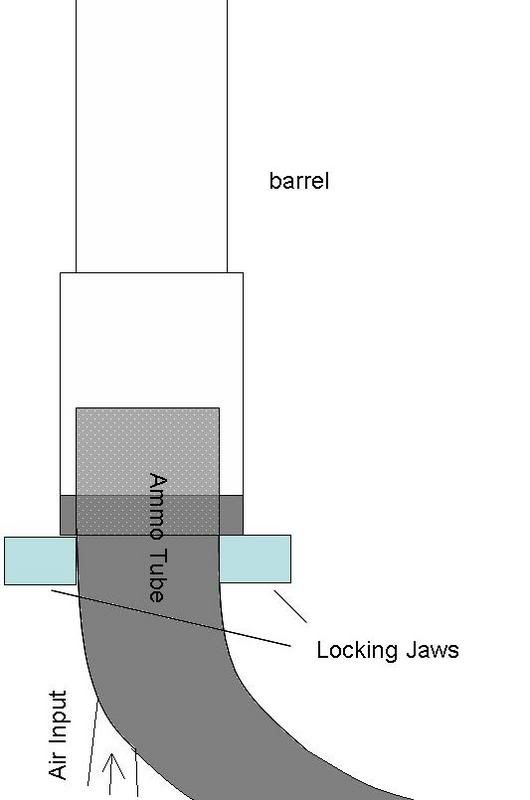

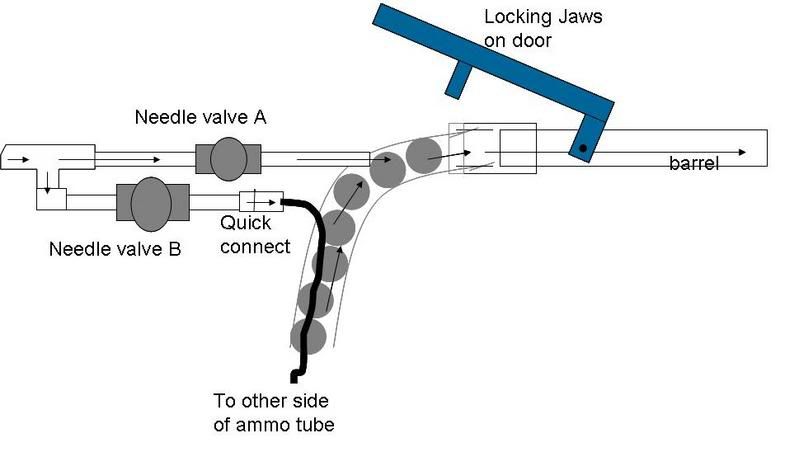

top veiw

side veiw

this design is for a Tube feed MG it should be easy to make a mock up belt fed MG with the design. the flow is mesured between the direct barrel flow and the tube flow. The tube flow is air that directly pushes the ammo from the end of a coiled tube filled with ammo. the second output is the direct barrel flow which exist so the rate of fire wont be too high and their will be a siphon (sp?) effect to allow some more direct airflow. The door with locking jaws holds the tube in so it can be reloaded like a real belt fed machine gun.

you might be thinking that the tube is not uniform enough and too flexible that it might crush paintballs (my main ammo idea), however I found some tubing in my shop that should work perfectly its very uniform and holds its round shape well yet is still flexible but I haven't tested it with any ammo since I don't have any, but it should still work

-

From_Hamsterdam

- Specialist

- Posts: 110

- Joined: Thu Feb 15, 2007 8:26 pm

Wed Mar 28, 2007 7:28 pm

i like the idea of using air to push the ammo out the mag. i would suggest using a pipe instead of a tube so you could add a air tight piston under the ammo to push them up and save air.

i think it might be very low powered depends on how much pressure is coming through A.

also it might be hard to connect the A pipe to the mag, it would be even harder if you are use more then one mag.

changing valve B to a gate or globe valve might give you better control of the flow.

All in all it's a good idea i hope it works out.

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

Wed Mar 28, 2007 7:52 pm

I could use a pipe rather than a tube but if I have the right tubing a coil of tubing could hold much more ammo than a pipe that would stick out

the airflow should be enough for paintballs or some marbles, sort of like a BBMG

I remeber I had a way to seal pipe A but I geuss casing the end of the tube in a tee or slant tee would work

also needle valves are extremely precise and designed for these applications, but since I might have to order one online It could work also with a difrent manual valve. I was thinking that I could eliminate one of the valve entierly but I'm not sure which.

-

From_Hamsterdam

- Specialist

- Posts: 110

- Joined: Thu Feb 15, 2007 8:26 pm

Thu Mar 29, 2007 7:52 am

What air supply are you planing on using?

I suggested globe or gate because it is easy to set it and keep it at a certain point. I found ball valves which are a lot like needle valves to be sensitive.

how long are you planing on making the tube? how many paint balls will it hold?

sound awesome hope you can show a vid when you make it

-

nate_003

- Private 2

- Posts: 29

- Joined: Fri Feb 09, 2007 9:01 pm

Thu Mar 29, 2007 8:51 am

iknowmy3tables wrote:well Its going to be a while befor I make a gun with this design I kinda feel guilty for not sharing this since its one of my better ideas

top veiw

side veiw

this design is for a Tube feed MG it should be easy to make a mock up belt fed MG with the design. the flow is mesured between the direct barrel flow and the tube flow. The tube flow is air that directly pushes the ammo from the end of a coiled tube filled with ammo. the second output is the direct barrel flow which exist so the rate of fire wont be too high and their will be a siphon (sp?) effect to allow some more direct airflow. The door with locking jaws holds the tube in so it can be reloaded like a real belt fed machine gun.

you might be thinking that the tube is not uniform enough and too flexible that it might crush paintballs (my main ammo idea), however I found some tubing in my shop that should work perfectly its very uniform and holds its round shape well yet is still flexible but I haven't tested it with any ammo since I don't have any, but it should still work

DANG!!!Iv been thincking about this idea for quit some time now exept i was going to use it as a way so i could carry paint balls on my back and get the balls to the gun

killjoy said and i quot "duct tape is a gift from god "

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

Thu Mar 29, 2007 2:59 pm

crazyfreak0075 wrote:I dont get how you are going to be able to regulate the ROF of the paintballs.

the direct barrel flow(from pipe A) cannot suck ammo as fast as the tube flow (from pipe B) can push ammo so to slow it down reduce the tube flow

top veiw

top veiw side veiw

side veiw