Help With Parts and sizes

- Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Made a basic cloud bbmg awhile ago, and due to lack of understanding made the chamber way to big, thus robbing eficiency and rof. ive decided to build another bbmg and am currently thinking the "go big or go home" mentality. As there is no where neere me that sells such things, im planning to order some clear 1 1/2 inch pvc (not so cheap) and some pvc rod to make end plugs AND the vortex block out of. i think a block made of rod would fit better than sheet, and could be shaped as to channel every last bb to the vortex hole. Now before anyone complains... i HAVE searched google AND the spudwiki AND the forum and i cant find a chart for internal pipe diameter. i know i saw one somewhere but cant find it again. i need to know the internal diameter of 1 1/2 pvc so i can know what size of pvc rod to order. My other question would refer to loading system. I hope to use a spring loaded plunger instead of a loading ramp, but im not sure what to make the front of the plunger out of. If all else fails i could probably use some of my pvc rod (that would work quite well actually...) or if ALL else fails maybe hot glue. Big question is what to use as a spring. i cant think of a store that sells springs, so i could use some help there. Mcmaster has springs but only in extremely large weight loads unless i get them really tiny. where do you get those big but low strength springs i see on plunger loaders?... Mcmaster requires i order pipe in increments of 4 feet, so im going to hope to be making 2 guns, 1 airsoft one .177 bb. I can find 6mm pipe on mcmaster, but i already have some 1/4 brakeline and was wondering how that would compare to something a little more precise that i could get of of mcmaster.]

sum it up: What size pvc rod will fit in 1 1/2 inch sch40 pvc pipe?

where can i get a spring to us in the plunger loader?

sum it up: What size pvc rod will fit in 1 1/2 inch sch40 pvc pipe?

where can i get a spring to us in the plunger loader?

-

spudzinger

- Specialist

- Posts: 135

- Joined: Thu Feb 02, 2006 3:17 pm

Ok, no offense but, use shorter, clearer sentences. I don't get half the stuff your talking about. For example when using an acronym such as rate of fire, write it as ROF instead of rof. When everything is in the same case and nearly the same sentence it is much harder to understand. Sorry if this causes you offense but its for your own good. Spudzinger

- Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Not sure what capitalizing an acronym has to do with short sentences. i see nothing wrong with combining several related and similar thoughts into one sentence. If you really find it hard to understand, im sorry but i dont see anything specifically confusing. Not trying to be overly rude but i would appreciate answers to my two basic questions, which are written at the bottom in case anyone had difficulty extracting them from my long sentences, much more than i would like grammatical advice. I could have rambled some but i am very confident that it is understandable.

-

spudzinger

- Specialist

- Posts: 135

- Joined: Thu Feb 02, 2006 3:17 pm

ok, sorry I was overly harsh. Anyways I cant help with that as I have never really done this sort of thing. Sorry for being an ass. LOL Spud

now lets not argue and bicker over who killed who this is suposed to be a happy occation!- monty python

aaaany who http://www.harvel.com/pipepvc-sch40-80-dim.asp

aaaany who http://www.harvel.com/pipepvc-sch40-80-dim.asp

"Those who are different change the world. Those who are the same keep it that way"

- Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Not a problem, i know that people commonly just post stupid stuff without thinking, im sure ive done it sometimes. Could we get some posts with actual help now Please? Im sure some one must know the answers, they are not overly complicated, i just need some help with sizes and where to get a spring. wheres noname when i need him, hes the inline BBMG master right? This is annoying because i know i saw a internal pipe diameter chart once.... i THINK i might now the answer, as here: http://www.spudfiles.com/forums/viewtopic.php?t=164&

PCGUY says that 1 5/8 rod fits in a 1.5" female adapter with "minimal grinding" Female adapters are slightly larger than pipe i think, so i dont think that will work for me.

PS lukemc u posted while i was typing this... THANKS for that chart!

That says that 1.5" internal diameter is average 1.59" so 1.5" rod would fit pretty well.

PCGUY says that 1 5/8 rod fits in a 1.5" female adapter with "minimal grinding" Female adapters are slightly larger than pipe i think, so i dont think that will work for me.

PS lukemc u posted while i was typing this... THANKS for that chart!

That says that 1.5" internal diameter is average 1.59" so 1.5" rod would fit pretty well.

Last edited by Panzerfaust on Wed May 02, 2007 6:16 pm, edited 1 time in total.

-

spudzinger

- Specialist

- Posts: 135

- Joined: Thu Feb 02, 2006 3:17 pm

Yeah just use the URL that Luke left and look at the inside diameters. Spud

Gimme a sec, I don't check the forums every hour!Panzerfaust wrote:wheres noname when i need him, hes the inline BBMG master right?

If you have a lathe or something similar, just get some rod slightly larger than the pipe and lathe it down to fit perfectly.

As for springs, most hardware stores sell them. If you can't find any, then get some music wire and tightly wrap it around a cylinder to make your own spring.

- Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

So noname, i was wondering what you would think of making vortex blocks out of rod instead of sheet. I would think it would be a little harder to make the first cuts against a rounded surface, but once u get that done it would be fine. It would fit better inside the chamber, and since it would go all the way to the edge of the chamber, you could round and angle it so as to roll all the bbs into the vortex hole. I dont have a lathe, sadly. but if internal diameter is 1.59" and i can get 1.5" im not to worried about a 0.09" gap. i can wrap it with some teflon tape to fix that. What section would a hardware store sell large springs in? Is this lowes type hardware or the more home depot type?

No way will I ever make blocks out of rod. That means it'll cost more to make, which means people pay more. It'll be a hell of a lot harder to make, because I use a ruler, a hacksaw, a drill, and an assorted collection of files, which means it'll take longer, which means I'll charge more. It would also be a lot harder to make a "half block," as people are calling it. Also, you have no idea how sheet fits into pipe, do you?

I have no idea where any springs would be in Home Depot or Lowes, just ask an employee.

I have no idea where any springs would be in Home Depot or Lowes, just ask an employee.

- Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Im not suggesting you use it in your business, im just wondering if it is a sound concept. Sheet is, by definition, rectangular. pipe is round. without modification they will not fit well. Now you could round of the bottom of a piece of sheet to help, but a rod that fits on the inside of the pipe will fit perfectly with no modification. There is going to be a small distance between the bottom of a sheet vortex block and the bottom of the pipe around it. (not your half block version) i think there would a potential for bbs to end up there and not feed, or this could slow feeding some. bbs could also end up in the dead space past the vortex whole but before the end of the chamber. if your block made it all the ways to the walls of the chamber, the bbs could come into the vortex by riding on part of the block instead of the chamber pipe. you could then slant the edges around the vortex as to draw bbs into it. I think its a theory worth investigating, there might be advantages and for the extra 7$ the rod costs me (im ordering sheet too incase it dosent work) im willing to try. BTW noname, have you any actual comparative data to say your half vortex is better than a full one? the concepts that says it would be better seem sound, but has any one done any tests?

Sheet is rectangular, but thin enough to create about 1/8" of space between the walls and the sheet, which is filled in by glue when attaching the block, unless you use screws.Panzerfaust wrote:Sheet is, by definition, rectangular. pipe is round. without modification they will not fit well.

Another reason why the half block is better.Panzerfaust wrote:There is going to be a small distance between the bottom of a sheet vortex block and the bottom of the pipe around it. (not your half block version)

This is eliminated by grinding away the front section of the vortex hole.Panzerfaust wrote:bbs could also end up in the dead space past the vortex whole but before the end of the chamber.

Then BBs wouldn't get in.Panzerfaust wrote:if your block made it all the ways to the walls of the chamber

Well, my first block ever had a full hole, and then I started modifying it. It had feed problems when the BB count got below about 100, and didn't have a huge amount of power or ROF, as far as I could tell. I don't really have any recorded, really accurate data, but by placing a half block in a strafer, then switching to a full block in the same chamber, it reduced power (was unable to penetrate a can at 50 feet) and emptied about 3-4 seconds slower.Panzerfaust wrote:have you any actual comparative data to say your half vortex is better than a full one? the concepts that says it would be better seem sound, but has any one done any tests?

- Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

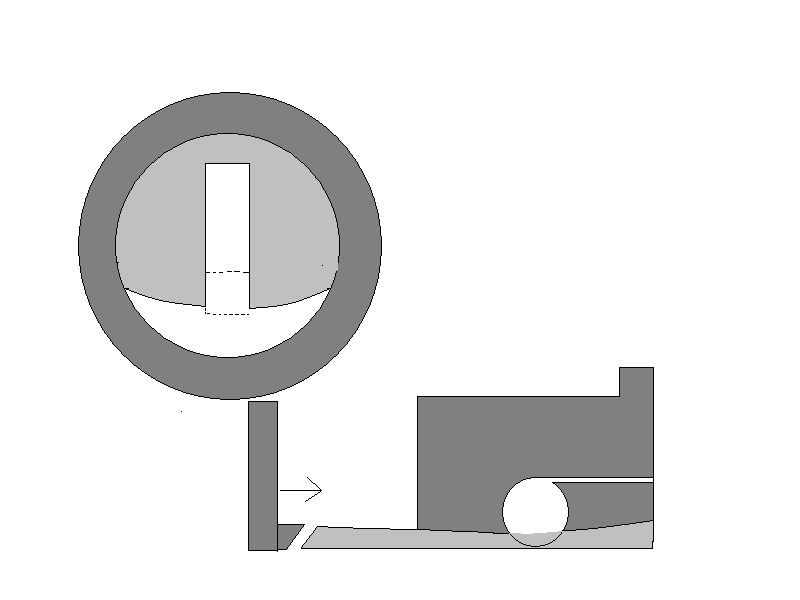

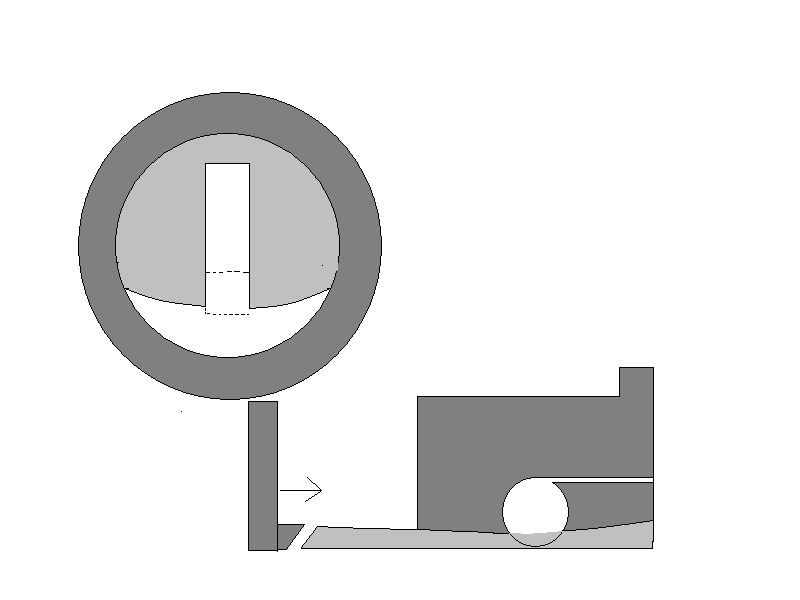

Your not really understanding me, the bbs would ride ON TOP of the material the vortex block was made of. Think of the back end of the vortex block as like an inverted loading ramp that goes towards the vortex hole. the bbs would be pushed by the plunger over a small hump, and then the vortex block material which fills the whole front of the gun could be shaped so that all bbs rolled towards the vortex hole. This is impossible to visualize or draw easily, so i understand that you cant get the idea.

I have decided that your Half block would be easier to make and sounds like it has some superior capabilites. my only worry is that as i intend to screw in my vortex block, that the gap below it cuased by the pipes roundness compared to the block's square edges might be big enough for bbs to fit into. i still think, however, that with full hole designs the slanted edges of my theoretical design would help feed to the last bb.

Hope this helps. Maybe my concept is stupid, but it seems doable to me. Picture did not come through too well. left one is view from back, right is view from side. the slashed line one the left one where supposed to show vortex hole location.

I have decided that your Half block would be easier to make and sounds like it has some superior capabilites. my only worry is that as i intend to screw in my vortex block, that the gap below it cuased by the pipes roundness compared to the block's square edges might be big enough for bbs to fit into. i still think, however, that with full hole designs the slanted edges of my theoretical design would help feed to the last bb.

Hope this helps. Maybe my concept is stupid, but it seems doable to me. Picture did not come through too well. left one is view from back, right is view from side. the slashed line one the left one where supposed to show vortex hole location.

- Panzerfaust

- Specialist

- Posts: 129

- Joined: Tue Apr 17, 2007 4:37 pm

Yes youve convinced me not to use it. Your half block does most of the things it does and is way easier. il go with that.