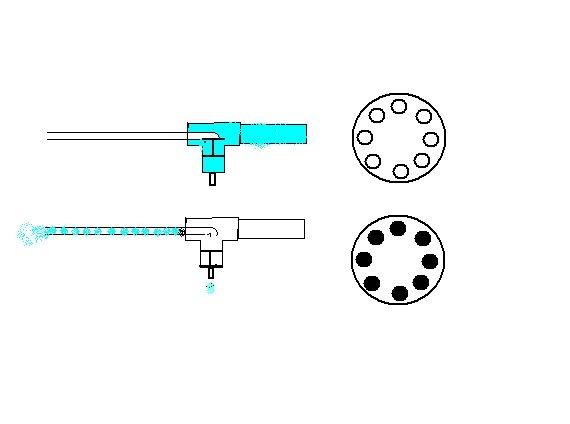

mopherman and I were talking at school today about a new type of piston valve that could be possible to make.

It's an inline piston. instead of having your chamber or barrel coming from the bottom of the tee your piston is. you hollow out a reducing brushing from 2 inch to 1 inch brushing so your pipe can slide through. then you put on a elbow to the 1 inch pipe which the piston will seal against.

also we have an idea for a check valve on the piston. you drill holes in a steel washer and put a rubber washer behind it. Also put a o ring so it slides and seals air around it. When air is pumped in the washer get pushed back at the holes allowing air to go into the chamber. When sucked back by the pilot the rubber get sucked against the holes. This alows no more then the air needed to leave from the pilot.

Heres a picture done on MS paint. the blue is air. The circle with little circles in it is a check valve for the piston.

http://i163.photobucket.com/albums/t310 ... iagram.jpg

New type of piston-inline

- paaiyan

- First Sergeant

- Posts: 2140

- Joined: Wed Dec 27, 2006 10:03 pm

- Location: Central Oklahoma

- Been thanked: 1 time

Picture no worky. Pissant, you beat me to it, now it does.

That looks as if it would work well, though you'll have to make sure there's enough pressure from the piston onto the barrel to keep the air from leaking, and doing it perpendicularly instead of in a linear fashion, you'll have to brace the barrel on the opposite side of the piston.

That looks as if it would work well, though you'll have to make sure there's enough pressure from the piston onto the barrel to keep the air from leaking, and doing it perpendicularly instead of in a linear fashion, you'll have to brace the barrel on the opposite side of the piston.

"Who ever said the pen was mightier than the sword, obviously, never encountered automatic weapons."

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

thats nothing fancy, plenty of people have proplly thought of the similar its just easier to make it non inline so you don't have to ajust the elbow, just look at commercial valves

these things have been done before.. I think

these things have been done before.. I think

Last edited by iknowmy3tables on Wed May 09, 2007 4:08 pm, edited 1 time in total.

- pyromaniac

- Corporal 4

- Posts: 805

- Joined: Tue Feb 27, 2007 7:18 pm

- Location: MO

There will be a spring keeping it sealed better inside of it.

Your last sentance confused me too.

Your last sentance confused me too.

:pottytrain3:

- paaiyan

- First Sergeant

- Posts: 2140

- Joined: Wed Dec 27, 2006 10:03 pm

- Location: Central Oklahoma

- Been thanked: 1 time

What I meant is, the pressure of the piston onthe barrel will bend it upwards, you'll need to brace it from the top to make sure that it stays sealed.

"Who ever said the pen was mightier than the sword, obviously, never encountered automatic weapons."

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

-

clide

- Corporal 3

- Posts: 784

- Joined: Sun Mar 06, 2005 3:06 am

- Location: Oklahoma, USA

- Been thanked: 1 time

Pretty much a homemade sprinkler valve. Longshot has built a few diaphragm valves with that configuration. http://www.spudfiles.com/forums/viewtop ... 0.html#640 has a cutaway of one.

- pyromaniac

- Corporal 4

- Posts: 805

- Joined: Tue Feb 27, 2007 7:18 pm

- Location: MO

O wow never saw that. thanks for the coments.

:pottytrain3:

I made this topic before, except it was for diaphragm valves instead. I also found out that it works fine, but you need something really strong on the backside of the barrel (eventually I just stuck in a PVC block).

lol, i just had that idea last night, but with a diaphragm instead. mine had a union where the piston is and there was an elbow in the tee.

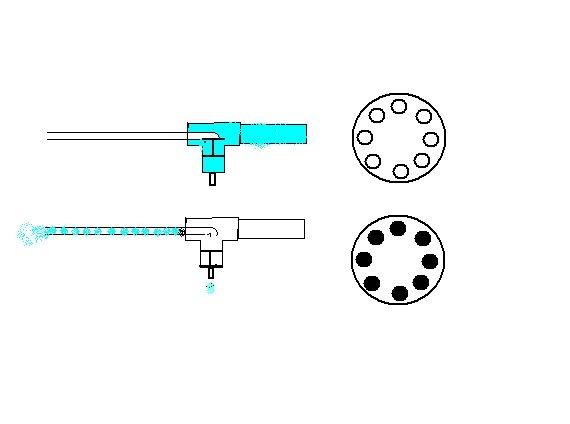

here is your picture

here is your picture

"physics, gravity, and law enforcement are the only things that prevent me from operating at my full potential" - not sure, but i like the quote

you know you are not an engineer if you have to remind yourself "left loosy righty tighty"

you know you are not an engineer if you have to remind yourself "left loosy righty tighty"

No, it won't. The force pushing the piston onto the barrel is exactly balanced by the force pushing on the barrel from the opposite side of the elbow.What I meant is, the pressure of the piston onthe barrel will bend it upwards, you'll need to brace it from the top to make sure that it stays sealed.

As a thought experiment, think of it as a vacuum in the barrel pulling on the piston. The physics are the same. Just like there's no force dragging you around the room when you put a stopper in a vacuum hose, there's no force acting to bend the barrel out of position.

Although I'm sure someone will tell me that I don't know what I'm talking about, your theory is flawed... The piston will push up against the elbow with however much pressure is behind the piston - at least until the chamber and pilot volume equalize... And there will be pressure enough to bend or snap the barrel inside the chamber... The amount of pressure won't be near zero, especially during the fill process... Remember, we're talking pressure and piston inertia, not vacuum... Once the two sides have equalized, however, you can then consider it to be a vacuum created from atmospheric pressure within the barrel that keeps the piston sealed...Freefall wrote:No, it won't. The force pushing the piston onto the barrel is exactly balanced by the force pushing on the barrel from the opposite side of the elbow.

As a thought experiment, think of it as a vacuum in the barrel pulling on the piston. The physics are the same. Just like there's no force dragging you around the room when you put a stopper in a vacuum hose, there's no force acting to bend the barrel out of position.

This is nothing new, I independently came up with an identical design on the UKSGC forum not too long ago when I was trying to invent a side venting valve that was better than a sprinkler valve.

It's the same issue of the piston acting sideways on the sealing pipe.

In a normal piston valve the piston is trying to compress a pipe lengthways - which is very easy to control.

In a side-sealing piston the piston is acting sideways on the pipe.

It's the difference between trying to crush a pen lengthways by hand or pressing it against the edge of a table.

If you really don't believe there is a sideways pressure on the pipe then ask yourself exactly what is keeping the piston face sealed to the barrel opening. That force is being constantly applied and is taken up by flex in the barrel. Enough force will cause problems.

I wouldn't use a valve like that for high pressure.

It's the same issue of the piston acting sideways on the sealing pipe.

In a normal piston valve the piston is trying to compress a pipe lengthways - which is very easy to control.

In a side-sealing piston the piston is acting sideways on the pipe.

It's the difference between trying to crush a pen lengthways by hand or pressing it against the edge of a table.

If you really don't believe there is a sideways pressure on the pipe then ask yourself exactly what is keeping the piston face sealed to the barrel opening. That force is being constantly applied and is taken up by flex in the barrel. Enough force will cause problems.

I wouldn't use a valve like that for high pressure.